The Versatility of Air Grinder Sanding Discs and Polishing Sanding Discs

2024.11.05

2024.11.05

Industry News

Industry News

Air grinder sanding discs and polishing sanding discs are indispensable tools that cater to a variety of applications. These discs are designed to provide precision and efficiency in shaping, smoothing, and polishing a wide range of materials.

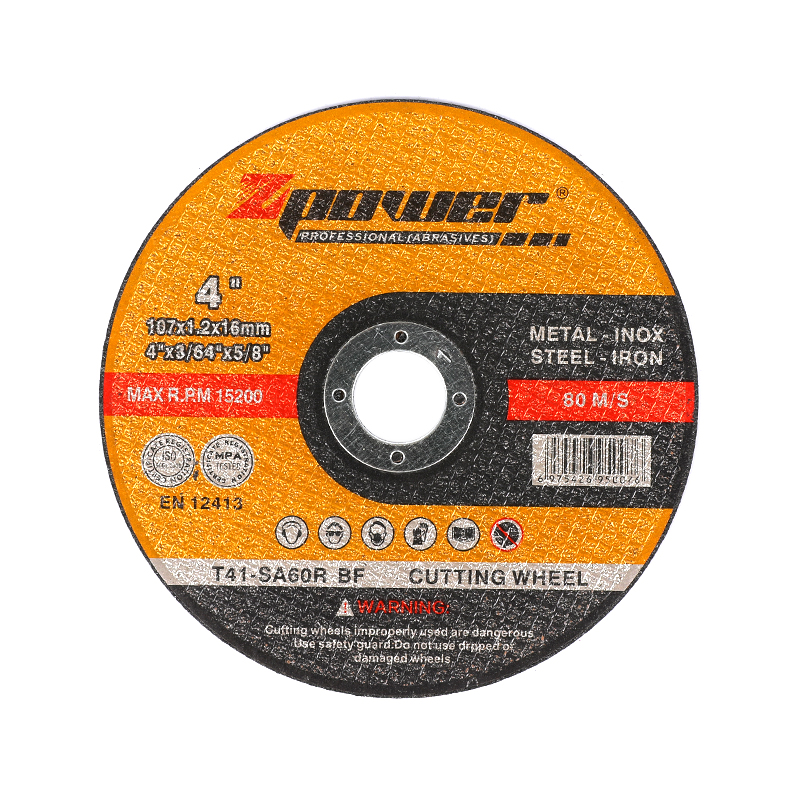

Air grinder sanding discs are known for their versatility and performance in various applications. These discs are designed to be used with air-powered tools, which offer the advantage of portability and ease of use. They are ideal for tasks such as deburring, material removal, and surface preparation on metals, plastics, and other materials.

The abrasive material on these discs, often made from aluminum oxide or silicon carbide, ensures a consistent and efficient sanding process. The ability to control the speed of the air grinder allows for precision work, making these discs suitable for intricate detailing and finishing tasks.

Air grinder sanding discs are designed for use with air-powered tools, offering a portable and convenient solution for various grinding and sanding tasks. These discs are known for their ability to remove material quickly and efficiently, making them ideal for heavy-duty applications such as metalworking, automotive repairs, and construction.

Material Removal: Air grinder sanding discs are engineered to remove material at a faster rate than traditional hand sanding methods. This is particularly useful when working with metals, where quick stock removal is necessary.

Versatility: These discs come in various grits, allowing users to choose the appropriate level of coarseness or fineness for their specific task. This versatility makes air grinder sanding discs suitable for everything from rough grinding to fine finishing.

Durability: Made from durable materials, these discs can withstand the rigors of heavy use, ensuring a long service life and reducing the need for frequent replacements.

Polishing sanding discs are the next step in the finishing process, designed to smooth surfaces and prepare them for a final polish or painting. These discs are finer than their air grinder counterparts and are used to remove minor imgoodions and achieve a high-gloss finish.

Surface Smoothing: Polishing sanding discs is essential for smoothing out minor imgoodions and scratches left behind by coarser grinding processes. They help in preparing surfaces for a final polish or painting, ensuring a flawless finish.

Fine Finishing: With their finer grits, these discs are good for fine finishing tasks. They can be used on a variety of materials, including wood, metal, and plastic, to achieve a smooth, even surface.

Compatibility: Polishing sanding discs are compatible with a range of power tools, including electric and pneumatic grinders, making them a versatile addition to any workshop.

The combination of air grinder sanding discs and polishing sanding discs offers a comprehensive solution for surface finishing. Air grinder sanding discs are used for initial material removal and shaping, while polishing sanding discs refine the surface, preparing it for a final polish or painting. This two-step process ensures that surfaces are not only smooth but also ready for the next stage of finishing, whether that be painting, plating, or another treatment.

In conclusion, air grinder sanding discs and polishing sanding discs are crucial tools in the surface finishing process. They offer a range of benefits, from material removal and surface smoothing to durability and versatility. By understanding the specific roles of these discs, professionals can achieve the desired finish on a variety of materials, ensuring a high-quality result every time.

Eng

Eng  عربى

عربى