The Impact of Circular Sandpaper and Metal Sanding Discs

2024.11.05

2024.11.05

Industry News

Industry News

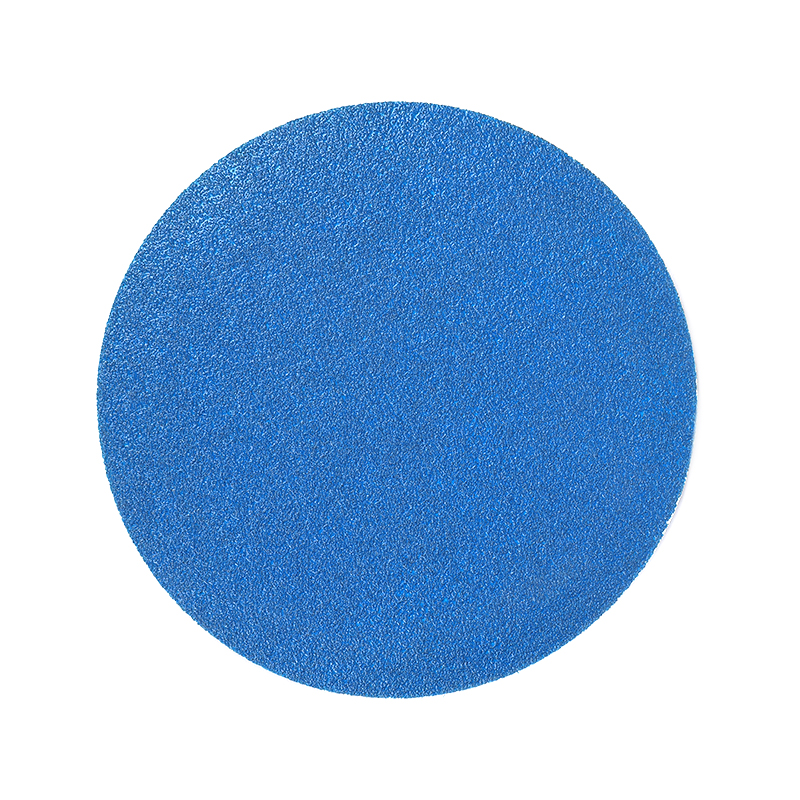

Sandpaper discs are versatile abrasive tools used for a variety of surface finishing tasks. They are circular pads coated with abrasive materials like aluminum oxide or silicon carbide, which help in smoothing, polishing, or shaping surfaces. These discs are compatible with power tools and can be used on metals, wood, and plastics. Their grit size determines the level of coarseness or fineness of the sanding, making them suitable for different stages of material preparation and finishing.

Circular sandpaper discs and grinder metal sanding discs are fundamental tools in the field of surface preparation and finishing. These discs are widely used across industries for their ability to smooth, shape, and polish various materials, including metals, wood, and plastics.

Circular sandpaper discs are a staple in workshops and factories due to their versatility. These discs are circular in shape and are attached to a backing pad or directly to a power tool, such as an angle grinder or a random orbital sander. The abrasive material on these discs can vary, with common types including aluminum oxide and silicon carbide, which are chosen based on the material being worked on and the desired finish.

The use of circular sandpaper discs is not limited to a single industry. In woodworking, they are used to smooth rough edges and prepare surfaces for painting or staining. In metalworking, they are essential for deburring, removing rust, and preparing metal surfaces for welding or plating. Automotive professionals also rely on these discs for bodywork repairs, where they remove paint and smooth out dents before refinishing.

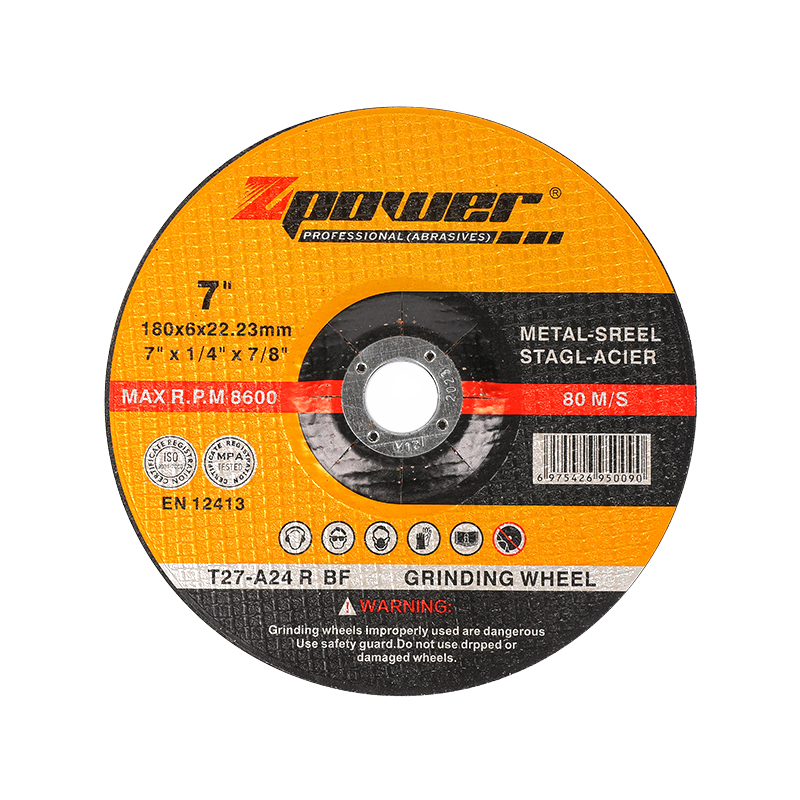

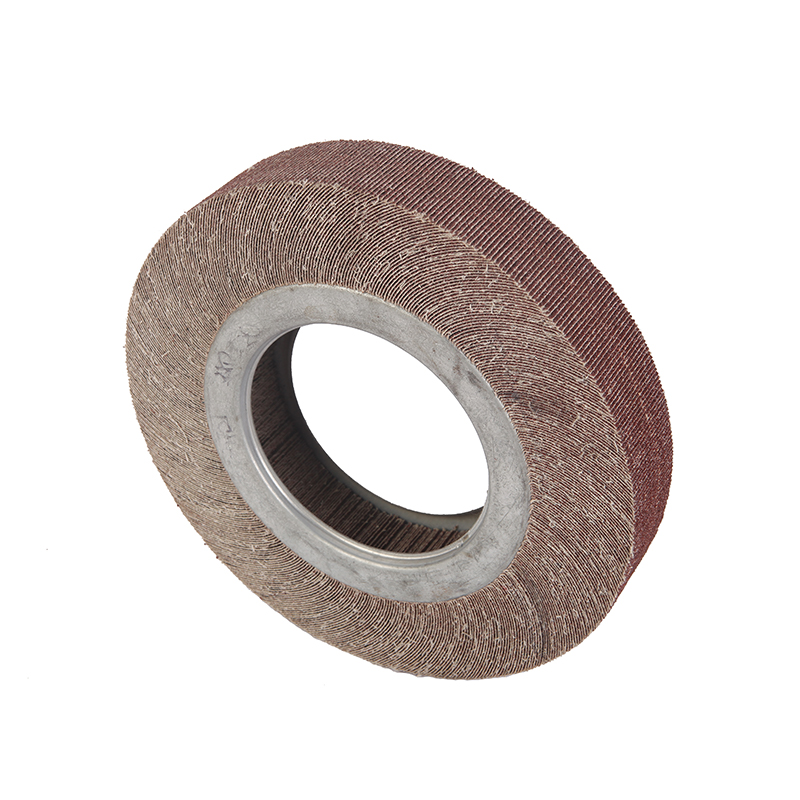

Grinder metal sanding discs are specifically designed for use with grinders and are tailored for working with metal. These discs are made from more durable abrasive materials to withstand the rigors of metalworking. They are thicker and more robust than standard sandpaper discs, allowing them to handle the high speeds and pressures associated with grinders.

The primary application of grinder metal sanding discs is in the removal of material and the preparation of metal surfaces. They are used to remove weld seams, smooth out castings, and prepare surfaces for painting or plating. The coarser grits are ideal for heavy stock removal, while finer grits are used for final polishing and finishing touches.

Both circular sandpaper discs and grinder metal sanding discs offer several benefits that make them indispensable in surface preparation:

Time Efficiency: These discs can quickly remove material and smooth surfaces, saving time compared to manual sanding methods.

Consistent Finish: The even distribution of abrasive particles on these discs ensures a consistent finish across the surface.

Versatility: With a range of grit sizes available, these discs can be used for various stages of surface preparation, from coarse grinding to fine polishing.

Cost-Effective: While the discs themselves may have a limited lifespan, they are relatively inexpensive, making them a cost-effective solution for regular use.

Safety: When used with the appropriate safety equipment and precautions, these discs can help reduce the risk of injury associated with manual sanding.

In conclusion, circular sandpaper discs and grinder metal sanding discs are essential tools for achieving professional-grade surface finishes. Their versatility, durability, and efficiency make them valuable assets in a variety of industries.

Eng

Eng  عربى

عربى