Exploring the Versatility of Steel Wire and Aluminum Oxide Grinding Wheels

2024.11.05

2024.11.05

Industry News

Industry News

Two of the more commonly used types of grinding wheels are Steel Wire Grinding Wheels and Aluminum Oxide Grinding Wheels. These wheels are indispensable in a variety of industrial applications, from heavy-duty metal removal to precision finishing tasks.

Steel Wire Grinding Wheels are known for their durability and strength. Made from high-carbon steel wires, these wheels are designed to withstand high pressure and heavy grinding loads. They are particularly effective in applications where high stock removal is required, such as in foundries and heavy engineering workshops. The steel wires are bound together with a strong bonding agent, which can be either resin, vitrified, or rubber, depending on the specific application needs. This binding allows the wheel to maintain its shape and integrity even under the more demanding conditions.

One of the key benefits of Steel Wire Grinding Wheels is their ability to stay cool during the grinding process. The open structure of the wheel allows for heat dissipation, which helps to prevent workpiece overheating and distortion. This is especially important when working with hard or tough materials that can generate a lot of heat during grinding. Additionally, the steel wires are self-sharpening, which means that as the wheel wears down, new cutting edges are exposed, maintaining a consistent cutting action and reducing the need for frequent wheel changes.

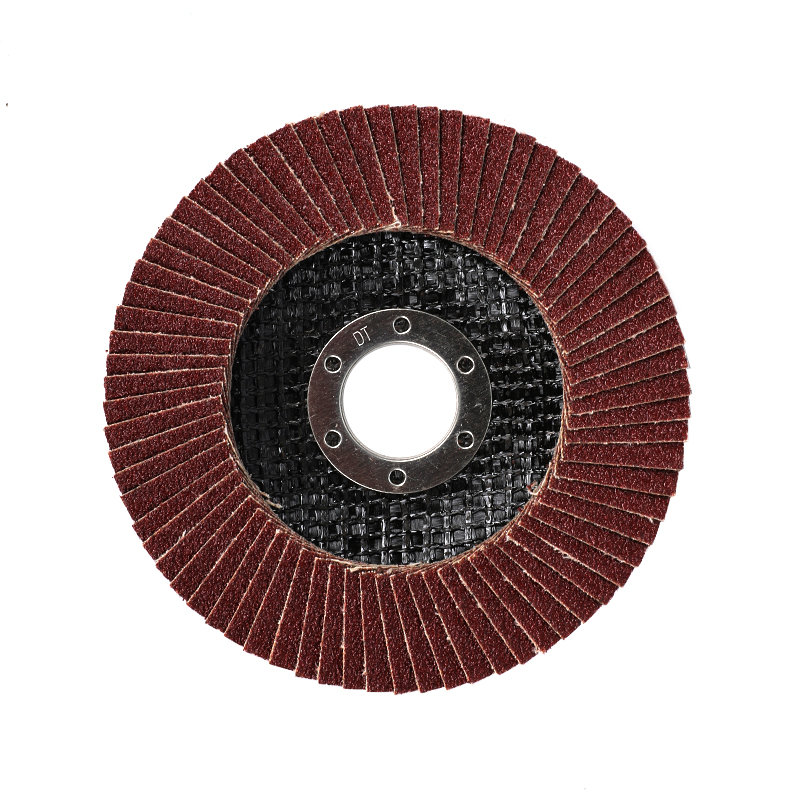

On the other hand, Aluminum Oxide Grinding Wheels are made from a different type of abrasive material. Aluminum oxide, also known as corundum, is a naturally occurring mineral that is second only to diamond in hardness. This makes it an material for grinding wheels that need to cut through a variety of materials, including steel, stainless steel, and cast iron. These wheels are known for their fast cutting action and long life, which can significantly increase productivity in many industrial processes.

Aluminum Oxide Grinding Wheels are available in various grain sizes, which determine the coarseness or fineness of the cut. A coarser grain size is suitable for heavy stock removal, while a finer grain size is better for finishing and polishing. The wheels can also be dressed to maintain their shape and cutting ability, which is a simple process that involves using a dressing stick or a diamond dresser to remove a small amount of material from the wheel's surface.

Both Steel Wire and Aluminum Oxide Grinding Wheels come in a range of sizes and shapes to suit different grinding machines and applications. They can be mounted on angle grinders, bench grinders, or pedestal grinders, and are used in a wide range of industries, including automotive, aerospace, construction, and manufacturing. The versatility of these wheels makes them a popular choice for many businesses looking to improve their grinding capabilities.

In terms of safety, it is essential to use the correct type of grinding wheel for the material being worked on. Using the wrong wheel can wheel failure and potential injury. It is also important to follow the manufacturer's guidelines for speed ratings and big operating temperatures to ensure the longevity and safety of the grinding wheel.

In conclusion, Steel Wire Grinding Wheels and Aluminum Oxide Grinding Wheels are two critical tools in the world of metalworking. Their unique properties make them suitable for a variety of applications, from heavy-duty grinding to precision finishing.

Eng

Eng  عربى

عربى