The Benefits of Cut-Off Wheels and Grinding Tools

2024.11.05

2024.11.05

Industry News

Industry News

Stainless steel, with its corrosion resistance and strength, is a popular material for these tools.

Grinding tools are essential for metalworking, offering precision and durability. They are designed to smooth, shape, and finish metal surfaces, enhancing product quality and efficiency in various industrial applications.

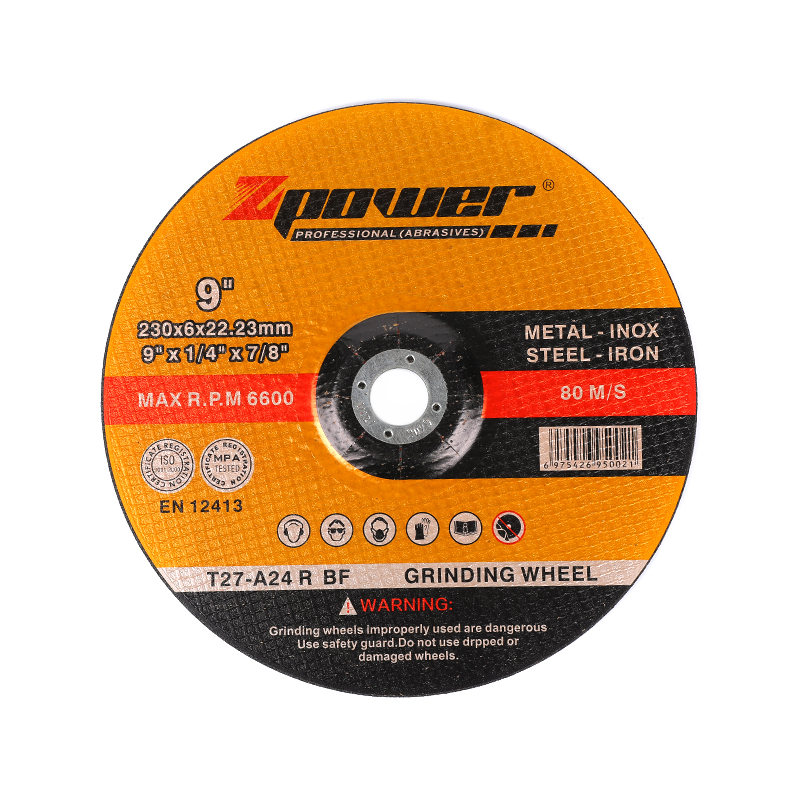

Stainless cut-off wheels are designed for cutting through stainless steel and other hard materials with precision and efficiency. These wheels are made with a blend of abrasive grains that are bonded together to form a disc with a specific diameter and thickness. The abrasive grains, often aluminum oxide or silicon carbide, are chosen based on the material being cut. The bond of the wheel determines its flexibility and the rate at which it cuts; a softer bond allows for faster cutting but less precision, while a harder bond provides more precision but at a slower rate.

Applications of stainless cut-off wheels are vast, ranging from cutting pipes and tubes to trimming metal sheets and structural components. They are also used in the fabrication of metal furniture, automotive parts, and various industrial equipment. The key to using these wheels effectively is to match the wheel's specifications to the material being cut, ensuring a clean, burr-free cut every time.

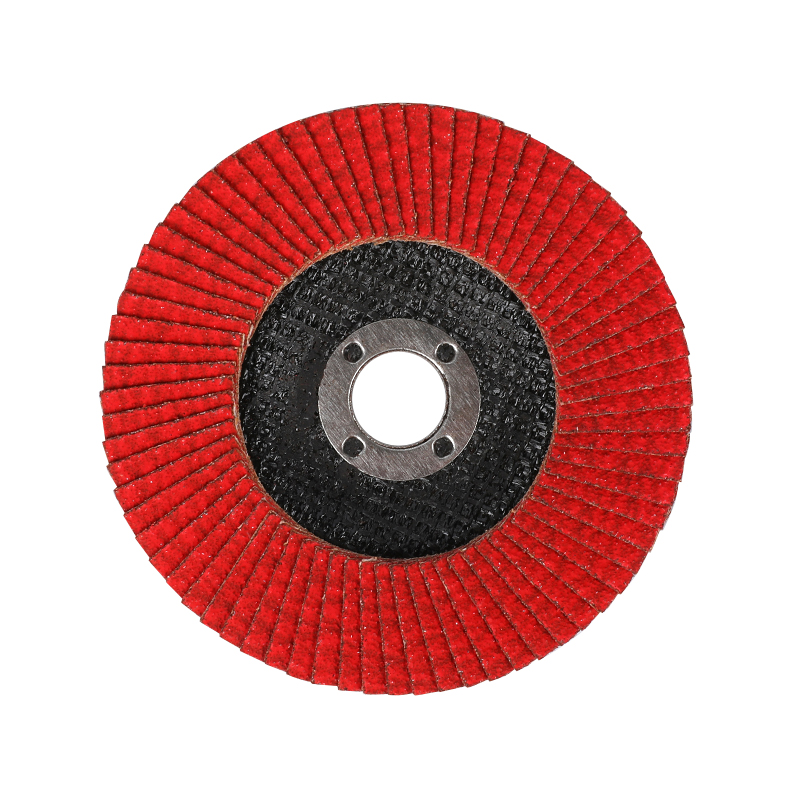

Stainless steel grinding tools, such as grinding wheels and flap discs, are used for shaping, deburring, and finishing metal surfaces. These tools are made from abrasive materials that are bonded to a stainless steel core, which provides both strength and durability. The abrasive grains, which can be the same as those used in cut-off wheels, are designed to remove material quickly and efficiently, leaving a smooth finish.

Grinding tools are essential in the final stages of metal fabrication, where a smooth, polished surface is required. They are used in applications such as preparing weld seams for painting, deburring machined parts, and removing rust or scale from surfaces. The choice of grinding tool depends on the specific task at hand, with different grit sizes and shapes available to suit various needs.

The use of stainless steel in cutting and grinding tools offers several advantages. ly, stainless steel's resistance to corrosion means that these tools can be used in damp or humid environments without fear of rusting. This is particularly important in outdoor construction or marine applications where tools may be exposed to the elements.

Secondly, the strength of stainless steel allows for the creation of thinner, more flexible grinding tools that can access tight spaces and contours that would be difficult for rigid tools to reach. This flexibility also reduces the risk of tool breakage during use.

Lastly, the durability of stainless steel means that these tools can withstand heavy use and maintain their shape and performance over time. This reduces the need for frequent tool replacement, saving both time and money in the long run.

In conclusion, stainless cut-off wheels and stainless steel grinding tools are indispensable in the metalworking industry. Their precision, durability, and versatility make them the preferred choice for professionals who demand the high quality results. By understanding the characteristics of these tools and matching them to the specific requirements of each job, metalworkers can achieve good performance and efficiency in their work.

Eng

Eng  عربى

عربى