About Us

YONGKANG ZHENGBO ABRASIVES CO., LTD.

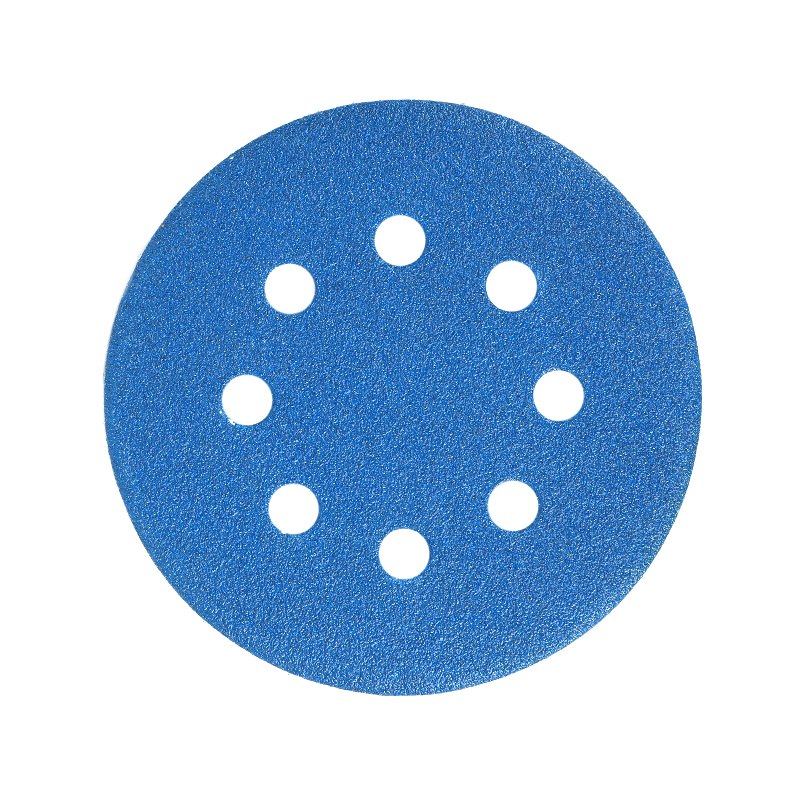

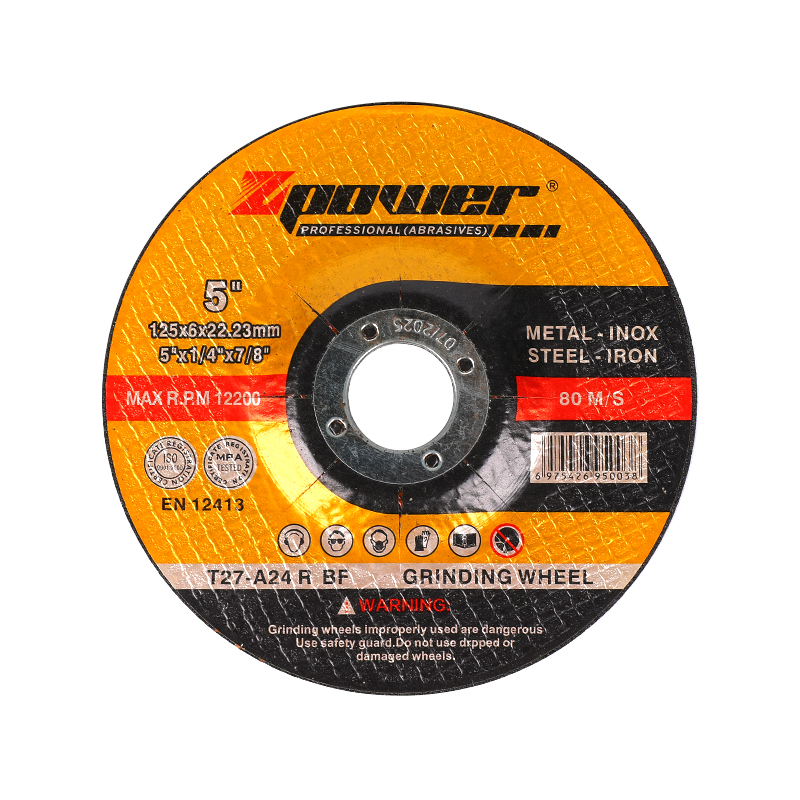

YONGKANG ZHENGBO ABRASIVES CO., LTD. is located in Yongkang, the hardware capital of China. It specializes in developing, producing, selling, and servicing wholesale Polishing Flap Wheel exporter and Polishing Flap Wheel supplier. It also operates flat abrasive cloth wheels, special fiber wheels, and steel wires: wheels and other abrasive products.

Established in 1995, the company has an annual output of more than 50 million grinding wheels. The company has a construction area of 12,000 square meters, more than 70 employees, and 10 R&D technicians. In the ups and downs of more than 20

years, step-by-step, down-to-earth, temper ourselves, develop and learn advanced production technology, improve the internal management system, keep pace with the times, and constantly seek to improve and improve product quality. Modern management, advanced

production technology, strict internal quality control, and timely after-sales service enable the company to respond to market changes, and customer demand, and provide the right products according to market and customer requirements. With a goal of 100 years of enterprise, Zhengbo is committed to technical research, product quality improvement, advanced production equipment updates, and the development of

suitable, cost-effective new products for market demand, we put more promotion funds into product research and development, to better quality and better service to the majority of users.

l am attentive, you can rest assured! Zhengbo Company adheres to the quality policy of “safe and efficient, quality and quantity, development and innovation, customer reassurance”, and establishes the concept of“realizing value for customers, development of customers is the development of enterprises", with“stable, honest, honest, and versatile”. "innovation, enterprising" is the spirit of enterprise, and constantly provides customers with reliable and valuable products. Provide OEM, ODM production, and OEM.

News

Eng

Eng  عربى

عربى