The Role of Metal Bond Cleaning Polishing Grinding Wheels

2024.11.05

2024.11.05

Industry News

Industry News

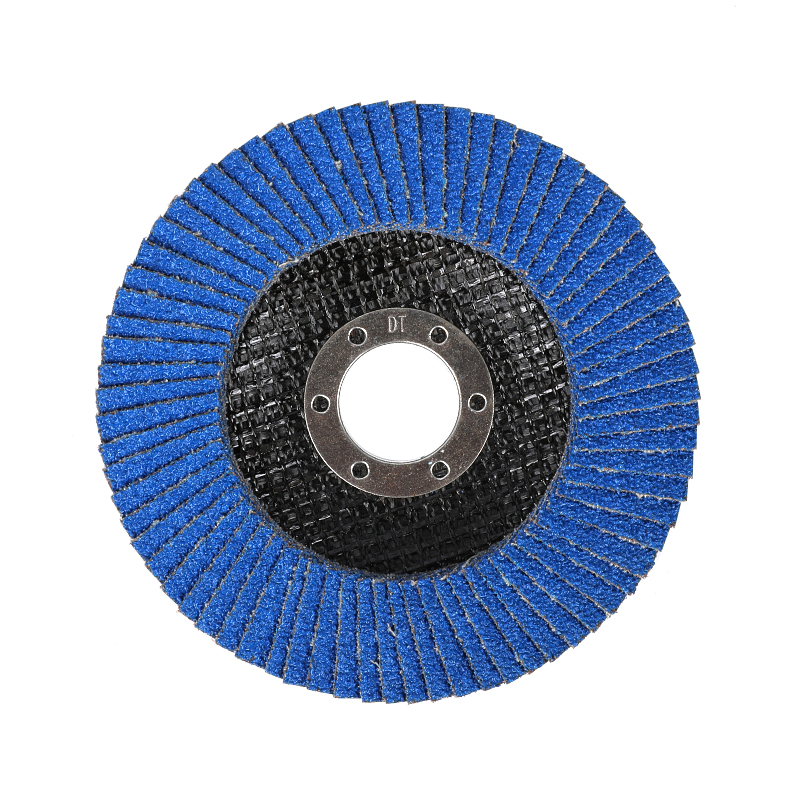

Metalworking is a critical process in various industries, from manufacturing to construction, where precision and efficiency are key. Metal bond grinding wheels, metal cleaning grinder discs, and metal polishing grinding wheels are essential tools in this field, each serving a distinct purpose to ensure good results.

Metal bond grinding wheels are known for their durability and strength, making them ideal for heavy-duty grinding applications. They are designed to withstand high pressure and heat, which is common in metalworking environments. Metal cleaning grinder discs are specifically engineered for removing rust, scale, and other surface imgoodions from metal surfaces, preparing them for further processing or finishing. Metal polishing grinding wheels, on the other hand, are used to achieve a smooth, shiny finish on metal surfaces, enhancing their aesthetic appeal and functional properties.

Metal bond grinding wheels are characterized by their robust construction, which includes a metal matrix that holds the abrasive grains in place. This metal matrix, typically made from materials like iron, brass, or steel, provides exceptional strength and heat dissipation properties. As a result, these grinding wheels are suitable for aggressive grinding tasks on hard metals such as stainless steel, titanium, and other high-strength alloys.

The metal bond ensures that the grinding wheel maintains its shape and structure even under heavy load, which is crucial for maintaining precision and consistency in the grinding process. Additionally, the metal bond allows for faster stock removal rates, which can significantly increase productivity in manufacturing settings.

Metal cleaning grinder discs are designed to remove surface contaminants from metals, such as rust, paint, and scale. These discs are typically made with a coarser grit and a more open structure, which allows for efficient material removal and prevents clogging. The abrasive grains used in these discs are often aluminum oxide or silicon carbide, which are effective at breaking down and removing surface imgoodions.

These discs are particularly useful in preparation for welding, painting, or other surface treatments, as they ensure a clean and uniform surface. The open structure of the disc also allows for better air circulation, which helps to keep the work area clear of dust and debris.

Metal polishing grinding wheels are the final step in the metal finishing process. These wheels are designed to produce a high-gloss finish on metal surfaces, enhancing their appearance and providing a protective layer against corrosion. The abrasive grains used in these wheels are finer than those used in cleaning discs, and the structure is often more dense to provide a consistent and smooth finish.

Metal polishing grinding wheels can be used on a variety of metals, including stainless steel, aluminum, and brass. They are particularly effective at removing minor scratches and imgoodions, leaving a surface that is both visually appealing and functional.

In conclusion, metal bond grinding wheels, metal cleaning grinder discs, and metal polishing grinding wheels each play a critical role in the metalworking process. From heavy-duty grinding to surface preparation and finishing, these tools are essential for achieving the desired results in metalworking applications. By understanding the unique properties and applications of each type of grinding wheel, professionals can select the appropriate tool for their specific needs, ensuring efficient and high-quality outcomes.

Eng

Eng  عربى

عربى