Understanding the Applications of Angle Grinder Cutting Tools

2024.11.05

2024.11.05

Industry News

Industry News

Angle grinders are versatile tools widely used in various industries for cutting, grinding, and polishing materials. Among the many accessories available, angle grinder aluminium cutting discs and thin grinder blades are particularly notable for their specific applications and performance characteristics.

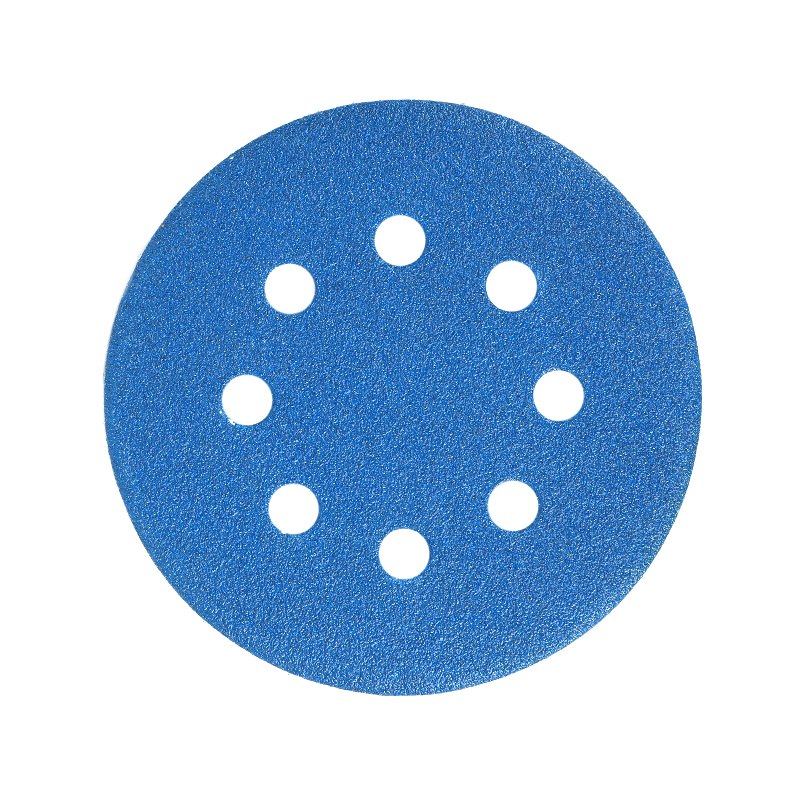

Angle grinder aluminium cutting discs are specially designed for cutting aluminium and other non-ferrous metals. These discs are constructed with fine grit abrasive that allows for smooth, efficient cutting without causing excessive heat buildup or material distortion. The unique design helps small burr formation and ensures clean edges, which is essential when working with delicate aluminium components.

When selecting the appropriate cutting tool, it’s essential to consider the specific material and the nature of the task at hand. For projects involving aluminium, using dedicated aluminium cutting discs will yield the good results, ensuring clean cuts without warping the material. Conversely, for tasks that require versatility across multiple materials, thin grinder blades provide a practical solution. Additionally, operators should always prioritize safety by using the right personal protective equipment and ensuring the tools are properly maintained.

One of the primary benefits of using aluminium cutting discs is their lightweight nature, which enhances the overall handling of the angle grinder. This feature is particularly important when performing extended cutting tasks, as it reduces operator fatigue and increases precision. Additionally, these discs are engineered to provide a balanced performance, allowing for stable cutting even at high speeds.

Aluminium cutting discs are also compatible with various angle grinders, making them a versatile choice for professionals and DIY enthusiasts alike. They are widely used in industries such as automotive, aerospace, and construction, where precision cutting of aluminium profiles, sheets, and extrusions is often required.

Thin grinder blades, often referred to as cutting blades, are designed for fast and efficient cutting of various materials, including metals, plastics, and composites. The thin design of these blades reduces friction during cutting, allowing for quicker, cleaner cuts and less material waste. This feature is particularly advantageous when working with materials that require minimal edge deformation.

The construction of thin grinder blades typically involves a robust steel core with a layer of abrasive material bonded to the surface. This combination provides both strength and flexibility, making the blades suitable for a range of applications. Users can choose from various grit sizes and materials to match the specific requirements of their projects.

Thin grinder blades are commonly used in metalworking, fabrication, and woodworking applications. They are ideal for tasks such as slicing through metal sheets, cutting pipes, and trimming composite materials. Their versatility makes them a staple in many workshops and manufacturing facilities.

Both angle grinder aluminium cutting discs and thin grinder blades offer distinct advantages that enhance productivity and efficiency in various cutting tasks. The precision and speed of aluminium cutting discs make them the preferred choice for non-ferrous metals, while the adaptability of thin grinder blades allows for a broader range of applications.

Moreover, the use of these tools can significantly reduce the time spent on cutting tasks, enabling operators to focus on other essential aspects of their projects. The clean cuts produced by both types of tools also reduce the need for additional finishing work, further streamlining the workflow.

In conclusion, angle grinder aluminium cutting discs and thin grinder blades are essential accessories for any angle grinder user. Their specific designs cater to various cutting needs, from aluminium and non-ferrous metals to a wide range of materials.

Eng

Eng  عربى

عربى