The Versatility of Resin, Flap Disc, and Timber Grinding Wheels

2024.11.05

2024.11.05

Industry News

Industry News

In the realm of abrasive technology, resin grinding wheels, flap disc grinding wheels, and timber grinding discs are three types of tools that play a role in various industries. Each serves a unique purpose and offers specific advantages, making them indispensable in their respective applications.

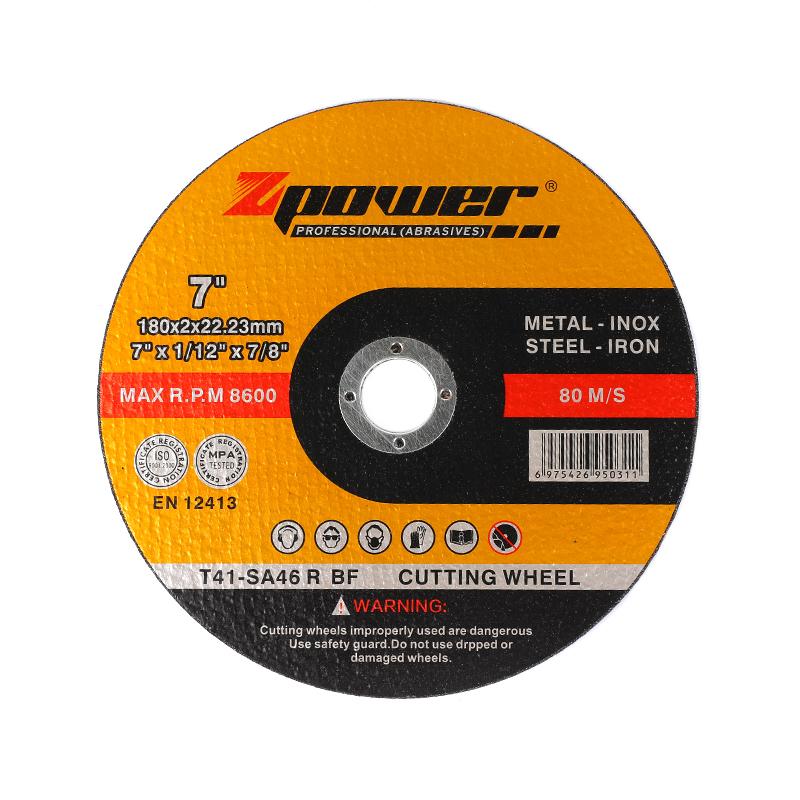

Resin grinding wheels are known for their versatility and durability. Made from a combination of abrasive grains and a resin bond, these wheels are designed to offer a balance between cutting speed and wheel life. The resin bond holds the abrasive grains together, allowing for a consistent and controlled grinding action. This type of grinding wheel is particularly effective for applications that require a fast stock removal rate without compromising the integrity of the workpiece.

Resin grinding wheels are suitable for a wide range of materials, including metal, stone, and concrete. They are often used in heavy-duty applications where high strength and heat resistance are required. The wheels can be found in various shapes and sizes, from small hand-held wheels to large, mounted wheels for industrial machinery. Their ability to withstand high operating temperatures and maintain shape under load makes them a popular choice for heavy grinding tasks.

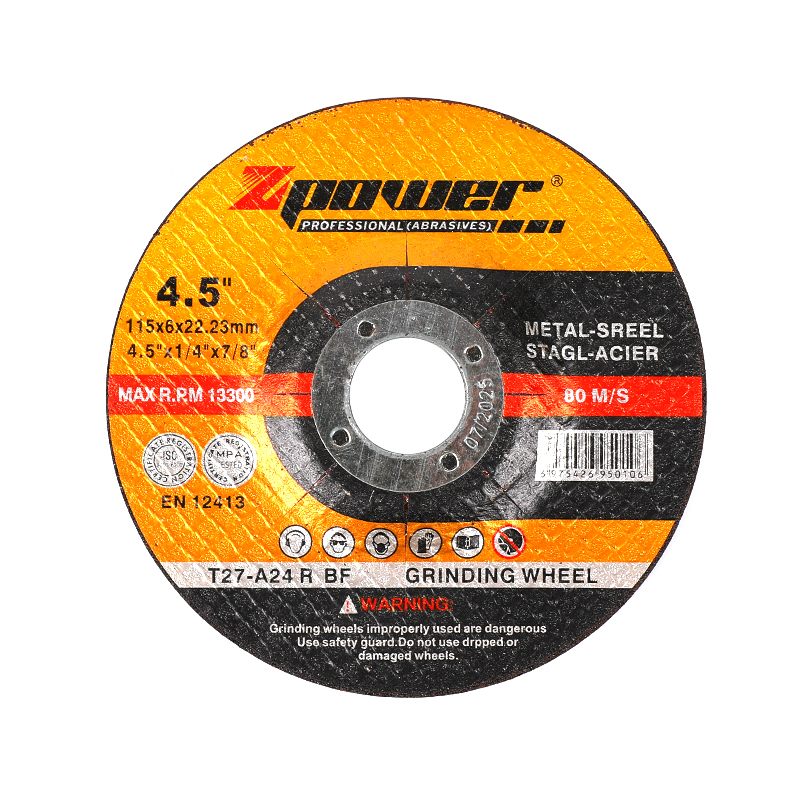

Flap disc grinding wheels are a type of abrasive tool that features a series of flaps or segments attached to a central hub. These flaps are made from abrasive material and are designed to provide a flexible grinding surface. The flexibility of flap discs allows them to conform to the shape of the workpiece, making them ideal for contoured surfaces and hard-to-reach areas.

Flap discs are known for their fast cutting action and efficient material removal. They are often used in applications where a high level of finish is required, such as in metal fabrication and automotive repair. The flexibility of the flaps also helps to reduce the risk of damaging the workpiece, as they can follow the natural contours of the material without applying excessive pressure to any one point.

One of the key benefits of flap disc grinding wheels is their ability to small heat build-up during the grinding process. This is due to the open structure of the flaps, which allows for better air circulation and heat dissipation. This feature is particularly important when working with materials that are sensitive to heat, as it helps to prevent thermal damage and maintain the integrity of the workpiece.

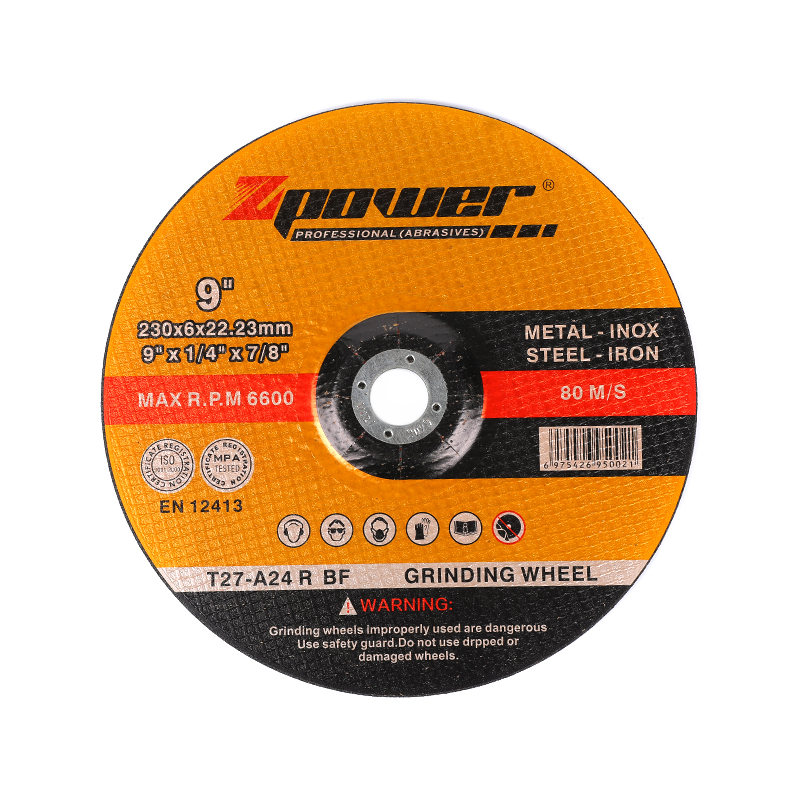

Timber grinding discs, as the name suggests, are specifically designed for use on wood and other organic materials. These discs are made from a combination of abrasive grains and a bond that is gentle enough to avoid damaging the wood while still providing effective material removal.

The primary use of timber grinding discs is in the woodworking industry, where they are used for tasks such as shaping, sanding, and finishing wood surfaces. They are particularly useful for removing rough edges, smoothing out knots, and preparing surfaces for staining or painting. Timber grinding discs are also used in the production of furniture, where they can help to achieve a consistent finish across large surfaces.

One of the key advantages of timber grinding discs is their ability to provide a smooth, even finish on wood surfaces. This is due to the fine abrasive grains used in their construction, which can remove material without leaving behind deep scratches or gouges. The discs are also designed to small the risk of splintering or tearing the wood, ensuring a clean, professional-looking result.

Eng

Eng  عربى

عربى