The Versatility of Sanding Discs and Pads in Surface Finishing

2024.11.05

2024.11.05

Industry News

Industry News

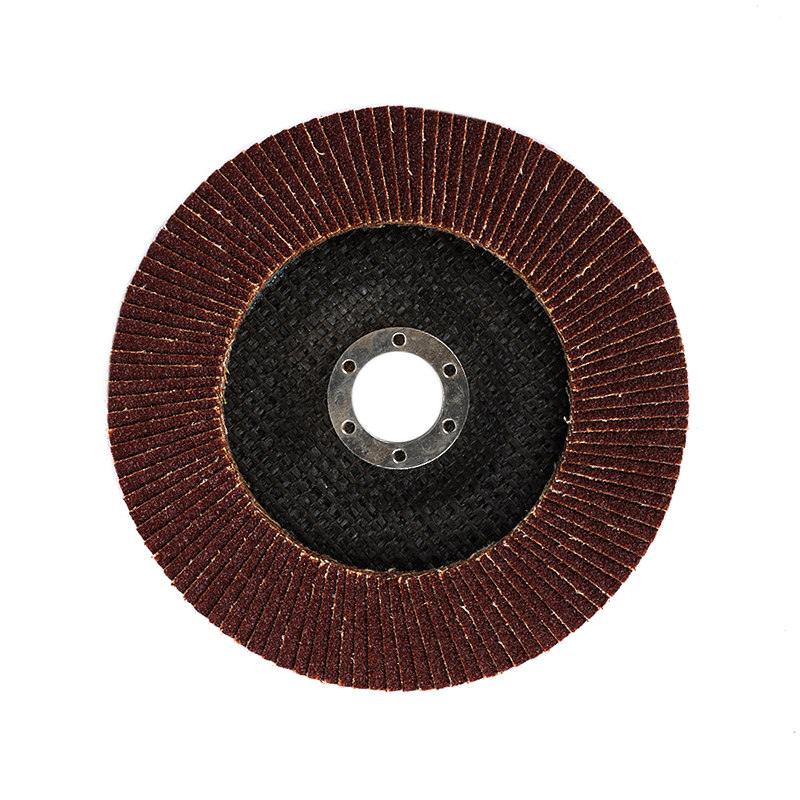

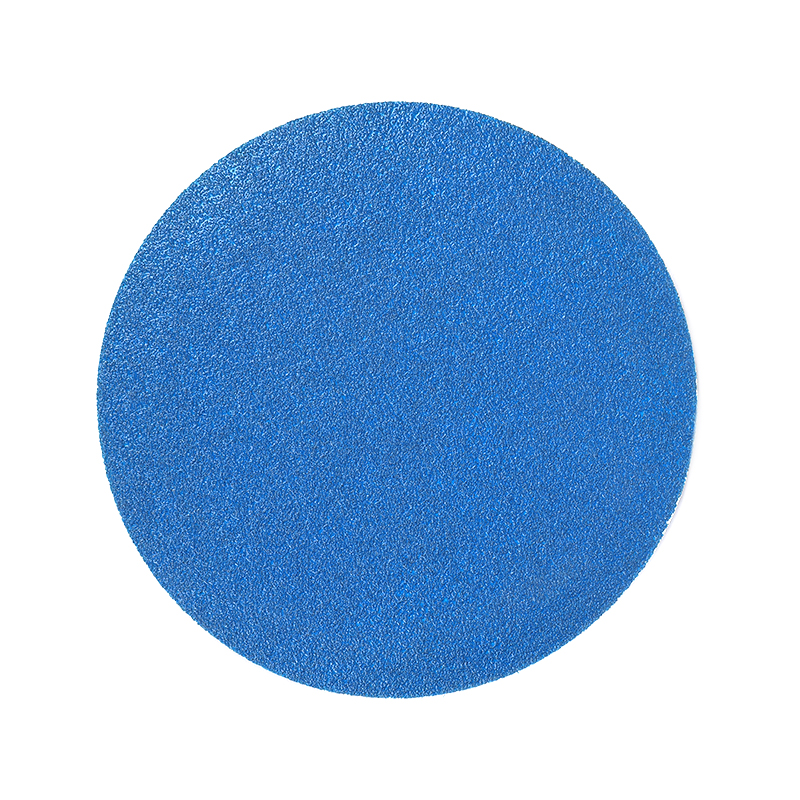

The use of sanding discs and pads is ubiquitous. These tools are essential for achieving a smooth and polished finish on a variety of materials, from wood and metal to plastic and more. Among the many types of sanding discs and pads available, silicon carbide sanding discs, drill press sanding discs, and small sanding pads stand out for their unique applications and benefits.

Silicon carbide sanding discs are known for their hardness and durability. These discs are made from a compound of silicon and carbon, which results in a material that is second only to diamond in terms of hardness. This makes them ideal for use on hard materials such as stone, ceramics, and glass. The sharp edges of silicon carbide particles cut quickly and efficiently, reducing the time required for sanding tasks. Additionally, these discs are resistant to heat and wear, which means they can be used for extended periods without losing their effectiveness.

Drill press sanding discs are designed to be used with drill presses, providing a controlled and precise sanding experience. These discs are typically smaller in diameter compared to other sanding discs, which allows for detailed work on intricate projects. The use of a drill press ensures that the sanding disc spins at a consistent speed, reducing the risk of uneven sanding or damage to the material being worked on. This precision is particularly valuable in applications where a high level of detail is required, such as in the creation of custom furniture or the restoration of antique items.

Small sanding pads offer a versatile solution for a wide range of sanding tasks. These pads are compact and can be used with a variety of backing plates, making them compatible with different power tools. The small size of these pads allows for sanding in tight spaces and on curved surfaces that larger discs cannot reach. They are also useful for sanding small items that would be difficult to handle with a larger disc. The portability and ease of use of small sanding pads make them a popular choice for both professional and DIY users.

Regardless of the type of sanding disc or pad, the choice of grit is crucial for achieving the desired finish. Coarser grits are used for initial shaping and removing material quickly, while finer grits are used for smoothing and polishing. A common practice is to start with a coarser grit and gradually work through finer grits until the desired level of smoothness is achieved. This step-by-step approach helps to prevent damage to the material and ensures a professional-looking result.

Proper maintenance of sanding discs and pads is essential for their longevity and effectiveness. After each use, it is important to clean the discs or pads to remove any debris that may have become embedded during the sanding process. This can be done using a brush or compressed air. Additionally, inspecting the discs or pads for any signs of wear or damage is a good practice to ensure they continue to perform at their good.

Safety should never be overlooked when using sanding tools. Always wear appropriate personal protective equipment, such as safety glasses and a dust mask, to protect against flying debris and dust. Ensuring that the work area is well-ventilated can also help to reduce the inhalation of dust particles.

Silicon carbide sanding discs, drill press sanding discs, and small sanding pads each offer unique advantages in the world of surface finishing. Whether working on a large-scale industrial project or a small-scale DIY endeavor, these sanding tools provide the means to achieve a high-quality finish that enhances the appearance and durability of any material.

Eng

Eng  عربى

عربى