The Role of Sanding Discs in Material Finishing

2024.11.05

2024.11.05

Industry News

Industry News

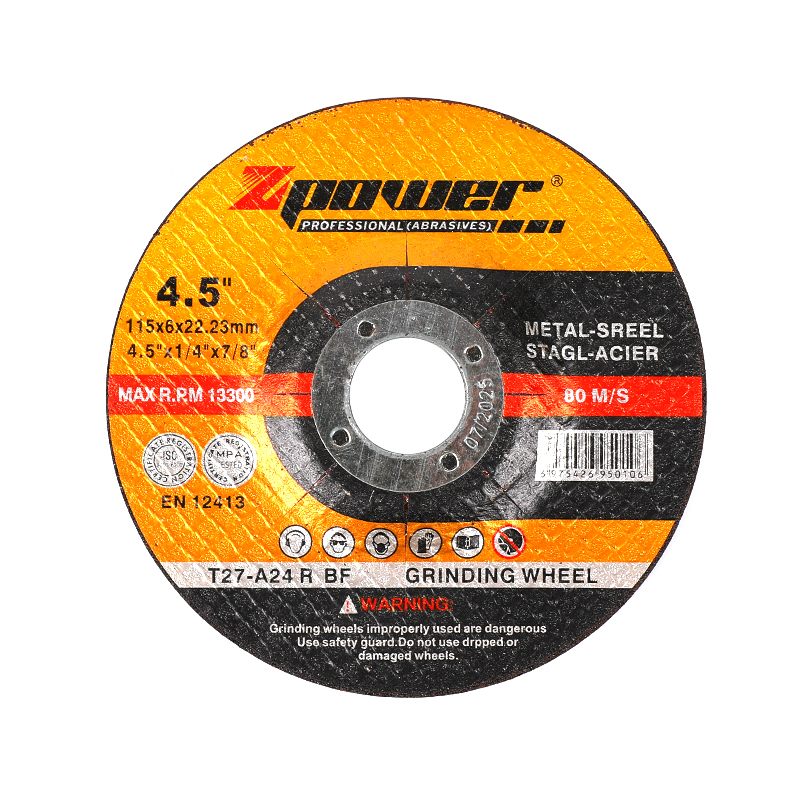

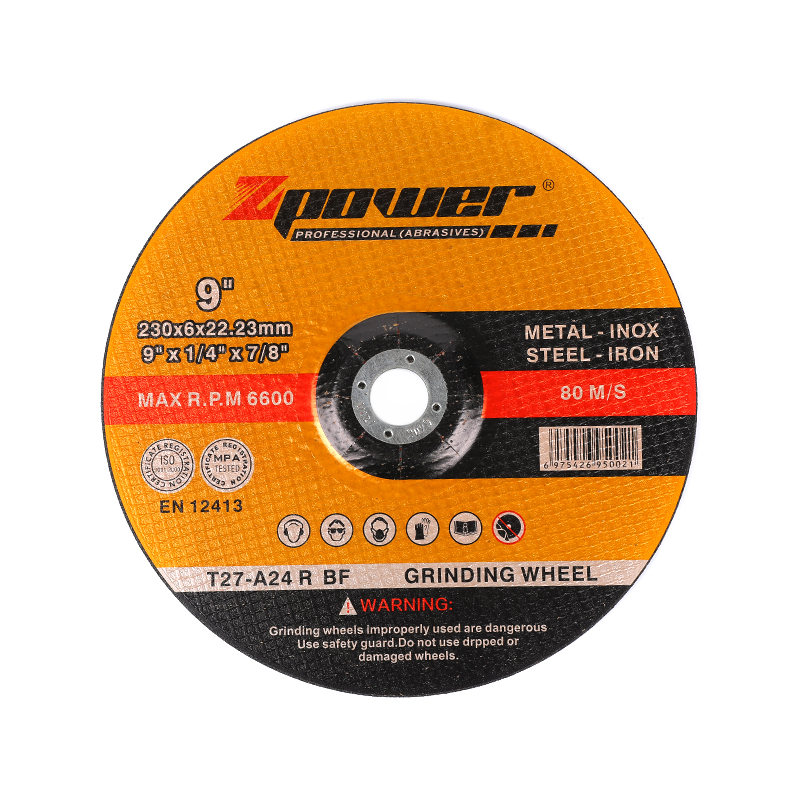

Sanding discs are indispensable tools in the world of material finishing, offering a range of options tailored to specific needs. Among these, aluminium sanding discs, epoxy sanding discs, and flap disc sanding pads are notable for their unique properties and applications.

Aluminium sanding discs are favored for their lightweight construction and durability. These discs are designed to withstand the rigors of heavy-duty sanding tasks without compromising on performance. The aluminium material provides a sturdy base that can handle high levels of abrasion, making it ideal for use on metals and other hard surfaces. The lightweight nature of aluminium also means that these discs are easy to handle, reducing user fatigue during extended periods of use. This makes aluminium sanding discs a popular choice for professionals and DIY enthusiasts alike.

These discs are designed to provide a consistent and efficient sanding process, especially on metal surfaces. They are known for their ability to withstand high temperatures and resist wear, which makes them ideal for heavy-duty applications. The aluminium material also ensures that the discs do not load up with dust and debris as quickly as other materials might, allowing for a longer sanding session without frequent disc changes.

Epoxy sanding discs are characterized by their use of epoxy as a bonding agent, which ensures a strong adhesion of the abrasive material to the disc's backing. This feature is particularly beneficial when working with materials that are prone to heat build-up or require a more secure bond to prevent the abrasive from detaching during use. Epoxy discs are versatile and can be used on a variety of surfaces, including wood, metal, and plastic. Their robust construction makes them suitable for both heavy-duty and precision sanding tasks, offering a reliable solution for a wide range of applications.

Flap disc sanding pads are known for their aggressive material removal capabilities and efficiency. These pads feature a unique design that allows for a larger contact area and faster stock removal compared to traditional sanding discs. The flaps are made from abrasive material and are mounted on a flexible backing, which allows them to conform to the contours of the workpiece. This design not only speeds up the sanding process but also helps to reduce the risk of scratches and other surface imgoodions. Flap disc sanding pads are particularly useful in industries where high productivity and surface finish quality are paramount.

Each type of sanding disc has its own set of applications and benefits. Aluminium sanding discs are often used in automotive and aerospace industries for their ability to handle tough materials and resist wear. Epoxy sanding discs are popular in woodworking and furniture making due to their versatility and secure adhesion. Flap disc sanding pads are a favorite in metalworking and heavy fabrication for their aggressive removal capabilities and adaptability to various shapes.

In conclusion, the choice of sanding disc depends on the material being worked on and the desired outcome. Aluminium sanding discs offer durability and lightness, epoxy sanding discs provide versatility in adhesion, and flap disc sanding pads deliver aggressive material removal.

Eng

Eng  عربى

عربى