The Versatility of Angle Grinder Conical Abrasive Sanding Sandpaper Discs

2024.11.05

2024.11.05

Industry News

Industry News

Conical sanding discs, abrasive sanding discs, and angle grinder sandpaper discs play a pivotal role. These versatile tools are essential for a wide range of applications, from wood and metalworking to automotive and construction industries.

Conical sanding discs are designed with a tapered shape that allows for easy access to hard-to-reach areas. Their conical shape is particularly useful for contoured surfaces and for sanding in corners or around edges. These discs are made from durable abrasive materials that can handle various types of materials, including wood, metal, and plastic. The ergonomic design of conical sanding discs reduces user fatigue during extended use, making them ideal for both professional and DIY applications. They are often used for deburring, smoothing, and polishing, ensuring a consistent finish with minimal effort.

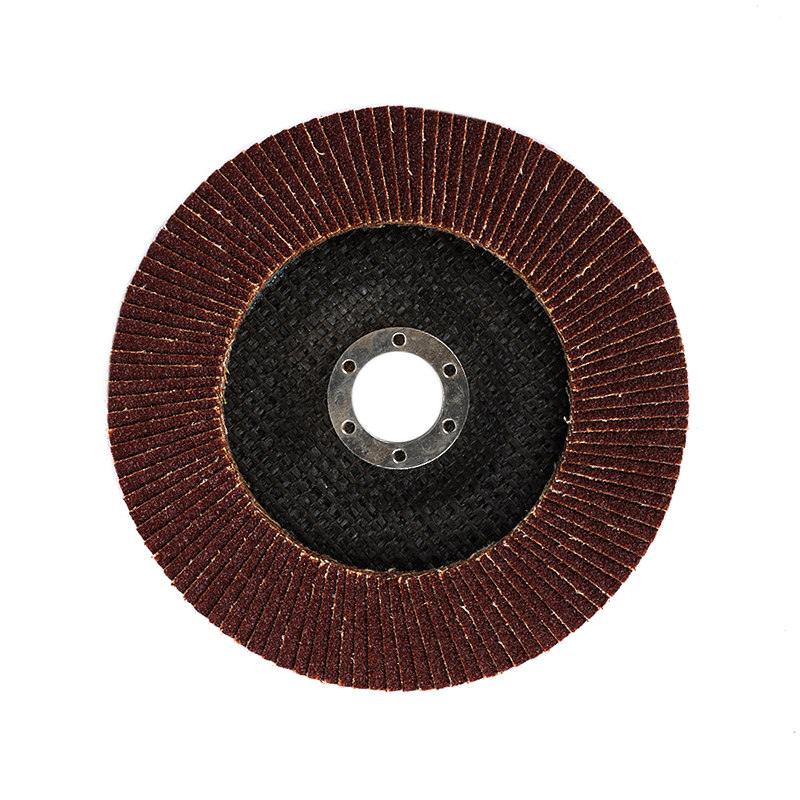

Abrasive sanding discs are known for their versatility and durability. These discs are made from a variety of abrasive materials, such as aluminum oxide or silicon carbide, which are bonded to a backing material. The choice of abrasive material depends on the material being sanded; for instance, aluminum oxide is suitable for wood and paint, while silicon carbide is better for metal. Abrasive sanding discs come in different grits, allowing for a range of finishes from coarse to fine. They are widely used in applications such as surface preparation, paint and rust removal, and material shaping. The durability of these discs ensures long-lasting performance, reducing the need for frequent replacements.

Angle grinder sandpaper discs are designed for use with angle grinders, providing a powerful and efficient way to sand and grind surfaces. These discs are made from a strong, abrasive material that can withstand high speeds and heavy-duty use. They are particularly useful for large-scale projects where speed and power are essential. Angle grinder sandpaper discs are used for tasks such as removing old paint, smoothing rough surfaces, and preparing surfaces for new coatings. The high-speed rotation of the angle grinder, combined with the abrasiveness of the sandpaper disc, allows for quick and efficient material removal.

The applications of conical sanding discs, abrasive sanding discs, and angle grinder sandpaper discs are vast. In woodworking, they are used for shaping, smoothing, and finishing wood surfaces. In metalworking, they are essential for deburring, grinding, and polishing metal parts. In the automotive industry, these discs are used for bodywork repair, rust removal, and general maintenance. In construction, they are invaluable for surface preparation before painting or coating.

The benefits of using these sanding discs include improved efficiency, reduced labor intensity, and enhanced surface quality. They allow for faster material removal and smoother finishes, which can save time and resources in the long run. Additionally, the variety of grits and materials available ensures that there is a suitable disc for every project, no matter the material or desired finish.

In conclusion, conical sanding discs, abrasive sanding discs, and angle grinder sandpaper discs are indispensable tools in the world of surface finishing. Their versatility, durability, and efficiency make them essential for a wide range of applications across various industries.

Eng

Eng  عربى

عربى