The Role of Power Grinding Wheels and Tool Sharpening Grinding Wheels

2024.11.05

2024.11.05

Industry News

Industry News

The use of power grinding wheels and tool sharpening grinding wheels is indispensable. These abrasive tools are designed to enhance productivity, ensure safety, and maintain the quality of work across various industries.

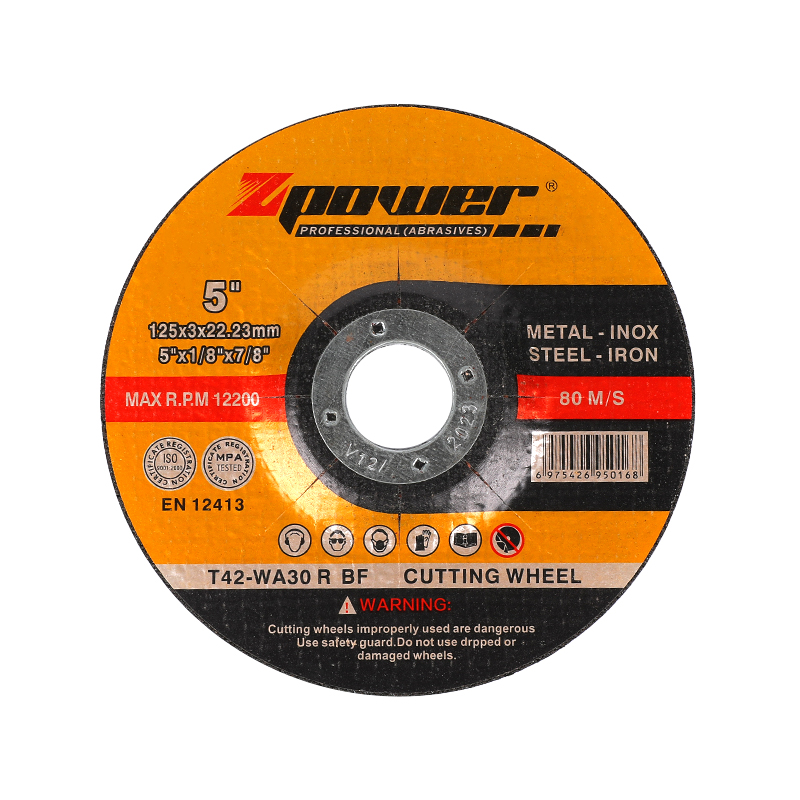

Power grinding wheels are engineered for heavy-duty applications where high removal rates and durability are required. These wheels are typically larger in diameter and thicker than standard grinding wheels, allowing them to handle the demands of power tools and machines. The construction of power grinding wheels often involves a dense arrangement of abrasive grains, which can be made from materials such as aluminum oxide or silicon carbide, depending on the material being ground.

The use of power grinding wheels is not limited to a single industry; they are employed in metal fabrication, automotive repair, construction, and aerospace, among others. Their robust design allows for faster stock removal and longer service life, which is particularly beneficial in environments where continuous grinding is necessary. The wheels are also available in various bond types, which affect their performance characteristics. For instance, a resin-bonded wheel offers a balance of strength and flexibility, while a vitrified bond provides higher heat resistance.

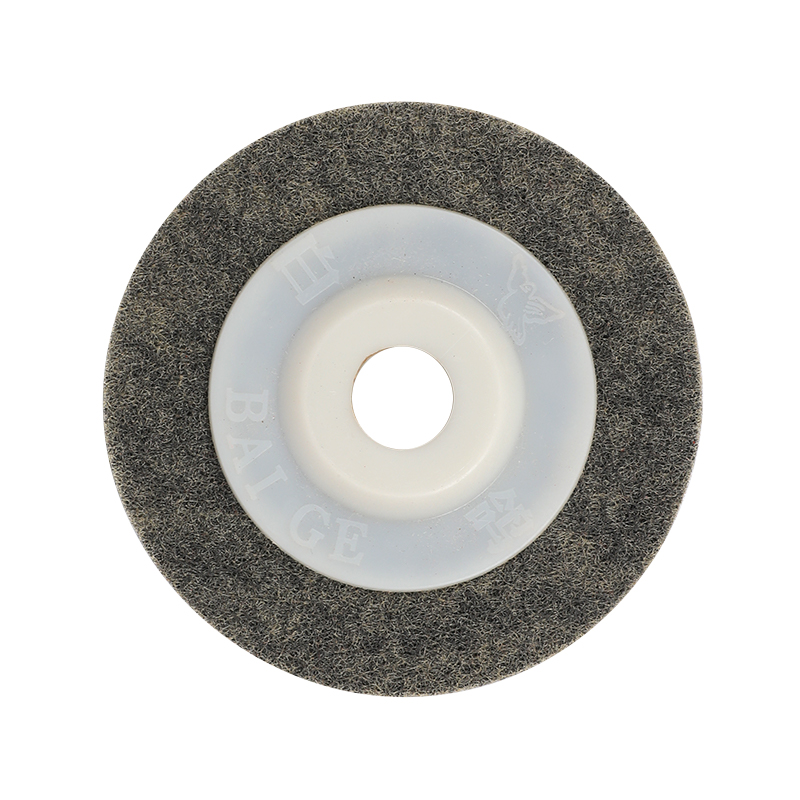

On the other hand, tool sharpening grinding wheels are precision instruments designed for the maintenance and restoration of cutting tools. These wheels are smaller and more delicate, with a finer grit size to ensure that the sharpening process does not damage the tool's edge. The abrasive grains in tool sharpening wheels are often arranged in a uniform pattern to provide a consistent and controlled sharpening action.

Tool sharpening grinding wheels are essential in maintaining the cutting efficiency of tools such as drills, chisels, and lathes. They are particularly important in industries where tool life directly impacts production costs and output quality. By using these wheels, manufacturers can extend the life of their tools, reduce downtime, and ensure that their tools maintain a sharp edge for good performance.

Both power grinding wheels and tool sharpening grinding wheels offer a range of benefits that contribute to the efficiency and safety of industrial operations. Some of these benefits include:

1. Enhanced Productivity: The use of grinding wheels can significantly reduce the time required for material removal and tool maintenance, pilot to increased productivity.

2. Improved Quality: Grinding wheels provide a consistent and precise finish, which is crucial for maintaining the integrity of the final product.

3. Cost-Efficiency: By extending the life of tools and reducing the need for frequent replacements, grinding wheels can help manufacturers save on costs.

4. Safety: The proper use of grinding wheels, along with the implementation of safety measures, can small the risk of accidents in the workplace.

5. Versatility: Grinding wheels are available in a variety of sizes, shapes, and grits, allowing them to be used in a wide range of applications.

In conclusion, power grinding wheels and tool sharpening grinding wheels are vital components in the arsenal of any precision manufacturing operation. Their ability to withstand heavy use and provide precise results makes them indispensable tools for achieving high-quality outcomes in a variety of industrial settings.

Eng

Eng  عربى

عربى