The Impact of Metal Sanding and Grinding Discs

2024.11.05

2024.11.05

Industry News

Industry News

Angle grinders are indispensable tools in the workshop, and their effectiveness is significantly enhanced by the right choice of grinding discs.

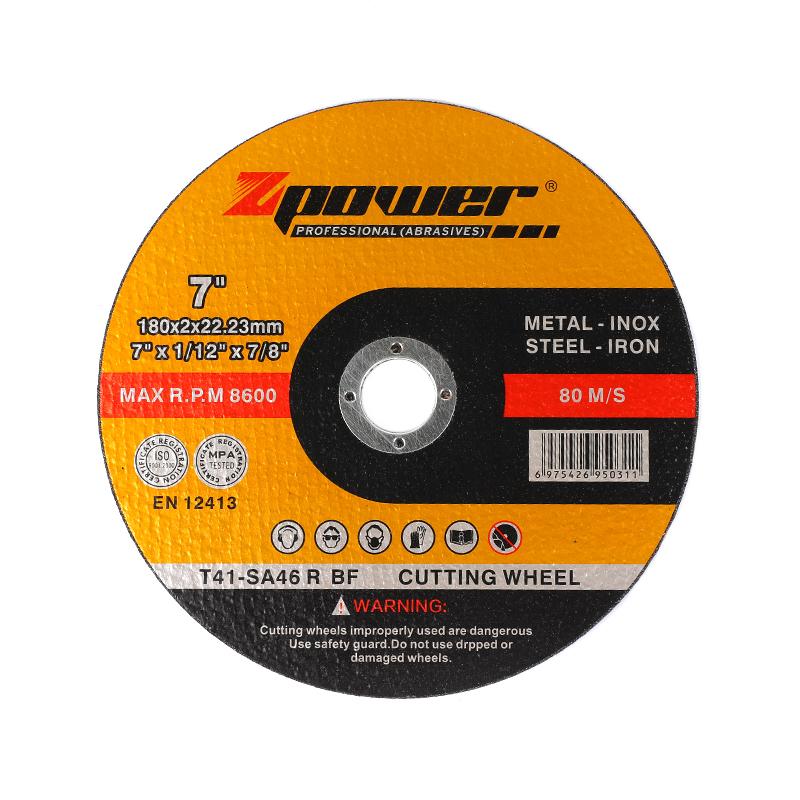

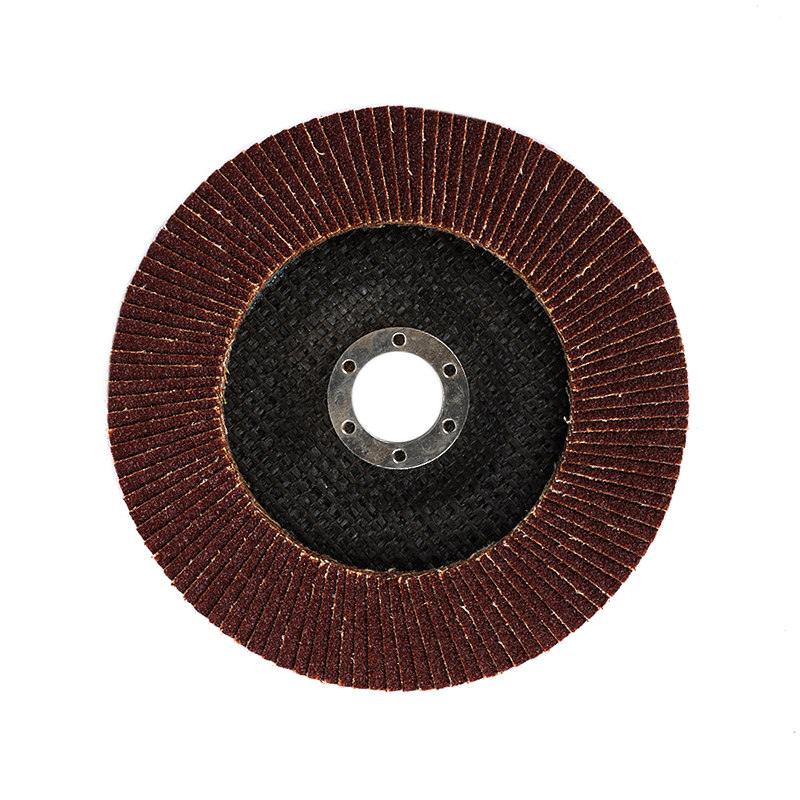

Grinding discs are abrasive tools used for cutting, shaping, and finishing metal surfaces. They are mounted on angle grinders and come in various grit sizes for different levels of material removal and surface finish. Made from materials like aluminum oxide or silicon carbide, these discs have a tough, durable structure that withstands high-speed grinding. They are essential in industries such as construction, automotive, and manufacturing for tasks like weld removal, deburring, and surface preparation.

Metal sanding discs are designed for heavy-duty grinding and sanding applications. These discs are made from abrasive materials that can quickly remove material and smooth surfaces. They are particularly useful for tasks such as deburring, rust removal, and surface preparation before painting or coating. The coarse grit of metal sanding discs allows for rapid material removal, making them ideal for the initial shaping and leveling of metal surfaces.

One of the key benefits of metal sanding discs is their durability. They are built to withstand the high speeds and heavy pressures that come with grinding metal. This durability means that they can be used for extended periods without needing to be replaced, which can save time and money in the long run.

For even more demanding applications, diamond metal grinding discs are the go-to choice. These discs feature diamond particles embedded in a matrix, which provides an ly aggressive cutting action. Diamond's natural hardness makes it the good material for grinding and cutting through the toughest metals, including stainless steel and hardened alloys.

The use of diamond grinding discs results in a cleaner, more precise cut compared to traditional abrasives. This precision is crucial in applications where the integrity of the metal's surface is paramount, such as in the aerospace or automotive industries. Diamond discs also have a longer lifespan than other abrasives, which can reduce downtime and increase productivity.

When using either metal sanding discs or diamond metal grinding discs, safety should always be a priority. These discs operate at high speeds, and incorrect usage can injury or damage to the workpiece. Always wear appropriate personal protective equipment, including safety glasses and hearing protection. Ensure that the angle grinder is in good working condition and that the disc is securely mounted before starting any grinding task.

Proper maintenance and storage of these discs are also crucial to their longevity and performance. After each use, clean the discs to remove any debris that may have become embedded during the grinding process. Store them in a dry place, away from moisture and temperatures, to prevent damage and maintain their effectiveness.

Angle grinder metal sanding discs and diamond metal grinding discs are powerful tools that can significantly enhance the capabilities of an angle grinder. By understanding the differences between these discs and choosing the right one for the job, professionals can achieve predominant results in metalworking applications. Whether it's for heavy-duty sanding or precision grinding, these discs are essential for any workshop that demands high-quality metal finishing.

Eng

Eng  عربى

عربى