The Versatility of Sanding Discs in Metalworking and Woodworking

2024.11.05

2024.11.05

Industry News

Industry News

In the world of metalworking and woodworking, sanding discs play a crucial role in shaping, smoothing, and finishing surfaces. Among the various types of sanding discs available, grinder sandpaper wheels, coarse sanding discs, and adhesive backed sanding discs stand out for their unique applications and benefits.

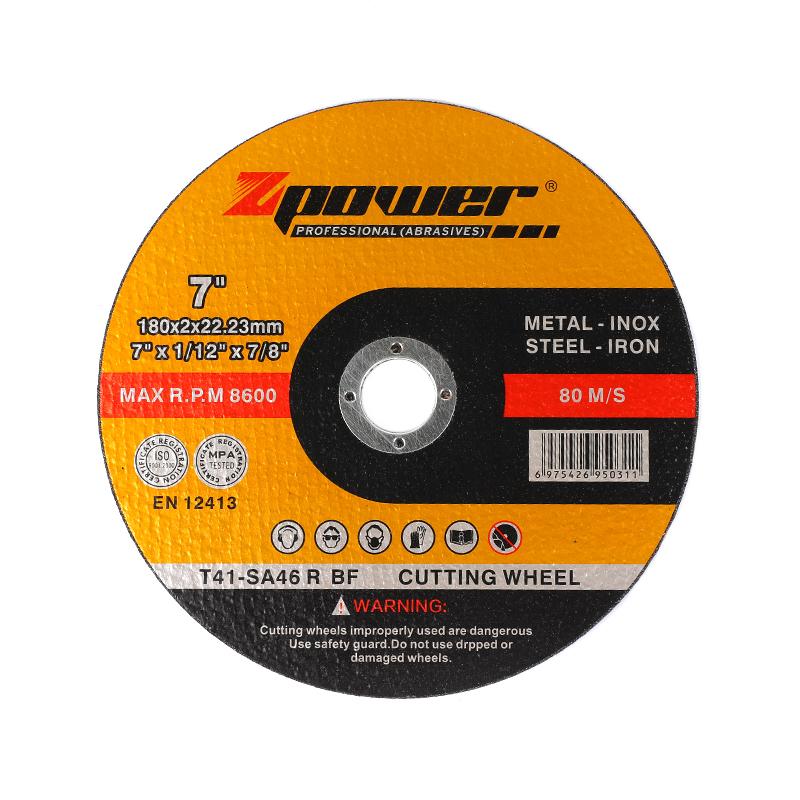

Grinder sandpaper wheels are versatile tools that can be used for a wide range of tasks, from heavy-duty grinding to fine finishing. These wheels are designed to be mounted on angle grinders, providing a powerful and efficient way to remove material quickly. They are particularly useful for tasks such as removing rust, smoothing welds, and preparing surfaces for painting or further finishing. The abrasive material on these wheels is designed to cut through metal and other hard materials with ease, making them a popular choice for professionals and DIY enthusiasts alike.

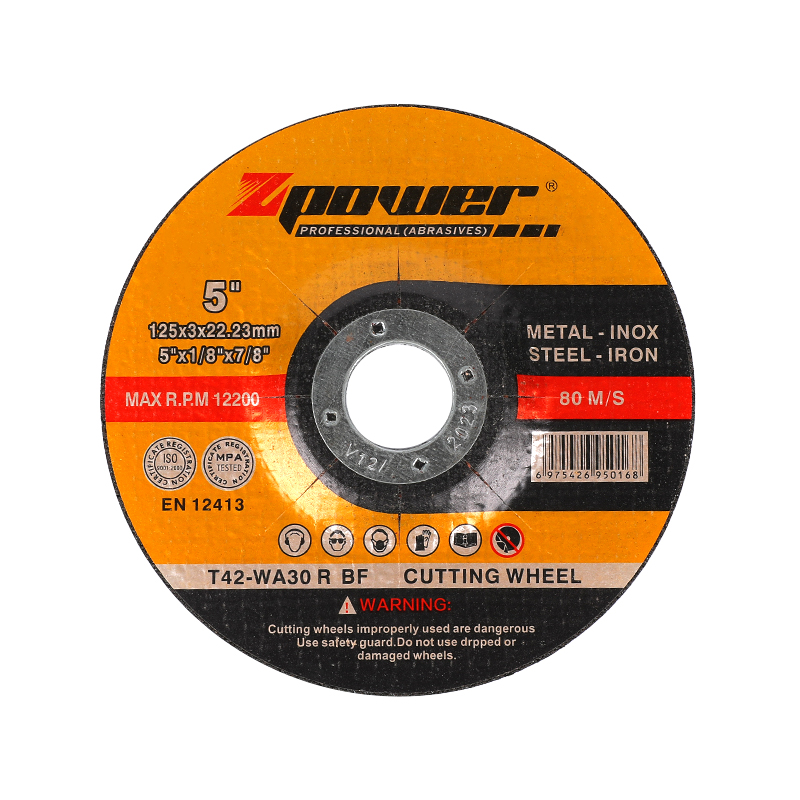

Coarse sanding discs, on the other hand, are ideal for initial shaping and rough sanding. They are made with a more aggressive grit, which allows them to remove material quickly and efficiently. These discs are good for taking down high spots, leveling uneven surfaces, and removing old paint or finish. The coarse grit is also beneficial for working with wood, as it can quickly remove large amounts of material without causing excessive heat or damage to the wood fibers. Coarse sanding discs are a must-have for any workshop, as they are the step in the sanding process.

Adhesive backed sanding discs offer a convenient and easy-to-use solution for a variety of sanding tasks. These discs feature a self-adhesive backing that allows them to be easily attached to a backing pad or a random orbital sander. This eliminates the need for additional clamping or mounting hardware, making them a popular choice for both professionals and hobbyists. Adhesive backed sanding discs are available in a range of grits, from coarse to fine, making them suitable for everything from heavy stock removal to final polishing. They are also ideal for use on contoured surfaces, as they can conform to the shape of the workpiece, providing even and consistent sanding.

One of the key benefits of using sanding discs is their ability to provide a consistent and even finish. Unlike hand sanding, which can be time-consuming and result in an uneven surface, sanding discs offer a more controlled and predictable sanding process. This is particularly important when working with wood, as an even finish is essential for a professional-looking result.

Another advantage of sanding discs is their durability. High-quality discs can withstand a significant amount of use before they need to be replaced, making them a cost-effective option for both small and large projects. Additionally, many sanding discs can be used with a variety of power tools, increasing their versatility and utility in the workshop.

When selecting sanding discs, it's important to consider the material being worked on and the desired outcome. For example, a coarse sanding disc may be necessary for initial shaping and stock removal, while a finer grit disc may be required for final finishing and polishing. It's also important to choose the right type of abrasive material for the job. Some discs are designed for use on metal, while others are better suited for wood or other materials.

In conclusion, sanding discs are an essential tool in any workshop, whether you're a professional craftsman or a weekend warrior. Grinder sandpaper wheels, coarse sanding discs, and adhesive backed sanding discs each offer unique benefits and applications, making them indispensable for a wide range of projects.

Eng

Eng  عربى

عربى