The Versatility of Sanding Discs in Material Processing

2024.11.05

2024.11.05

Industry News

Industry News

Among the many types of sanding discs available, soft sanding discs, adhesive sanding discs, and automotive sanding discs are particularly noteworthy for their specialized applications and effectiveness.

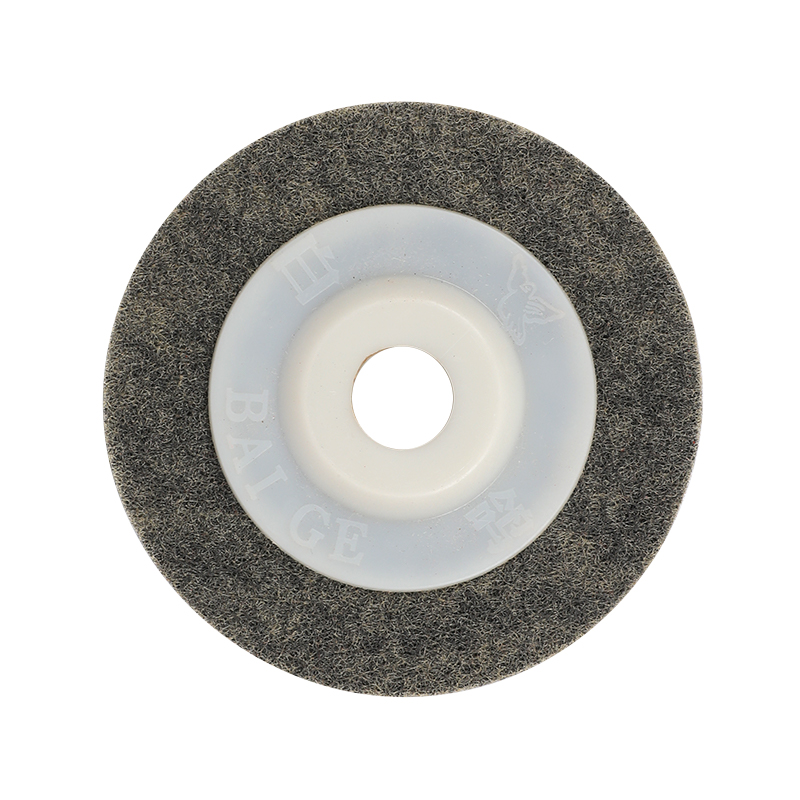

Soft sanding discs are designed for light to medium-duty sanding tasks where a fine finish is required without causing damage to the material. These discs are made with a lower grit rating, which means they have larger abrasive particles that are gentler on the surface being sanded. The softness of the backing material also contributes to the gentle action, making them ideal for use on softer materials or for final finishing touches.

One of the primary benefits of soft sanding discs is their ability to remove minor imgoodions without scratching the surface. They are commonly used in woodworking and automotive applications where a smooth, even surface is desired. For instance, in woodworking, soft sanding discs can be used to smooth the edges of wooden furniture or to prepare the surface for staining or painting. In the automotive industry, they are used to remove light oxidation and scratches from car paint before applying a new coat of paint.

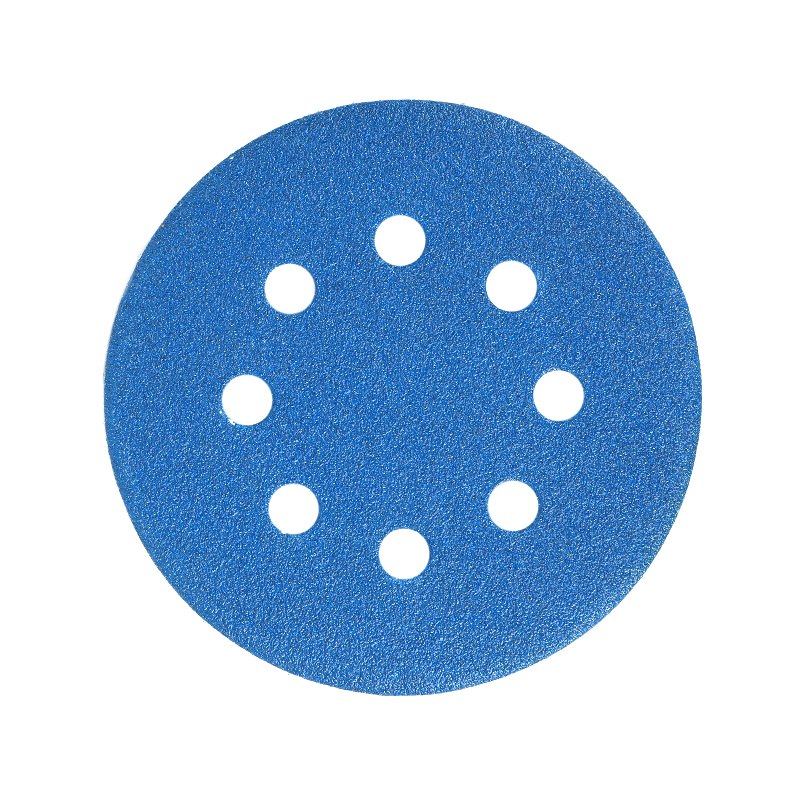

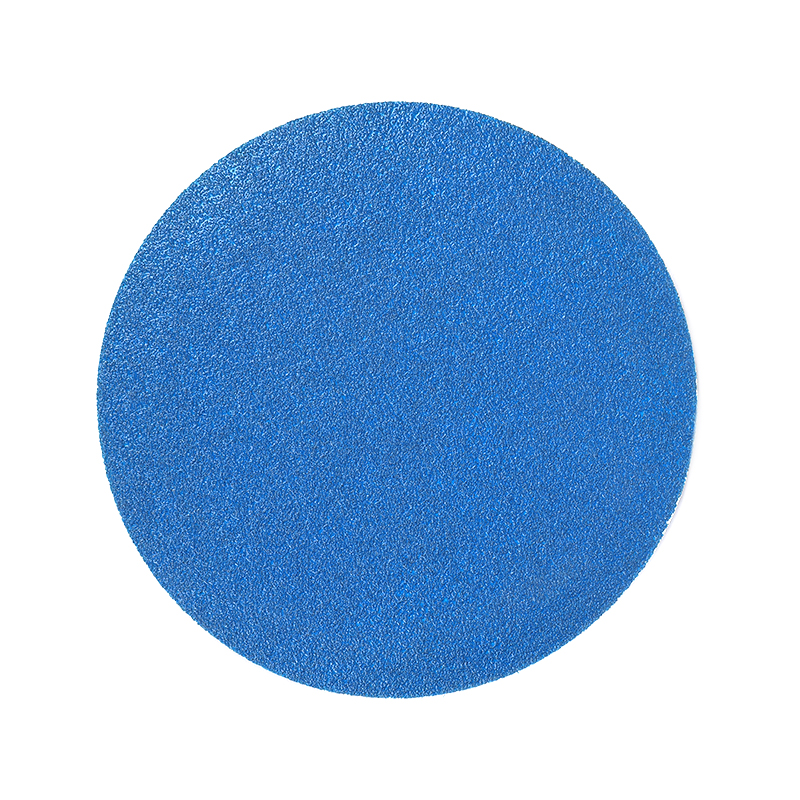

Adhesive sanding discs offer the convenience of easy attachment and detachment from the backing pad. These discs are designed with an adhesive backing that allows them to be quickly and securely attached to a sanding machine or a backing pad. This feature makes them ideal for situations where frequent changes of sanding discs are required, as it saves time and effort.

The versatility of adhesive sanding discs is further enhanced by their compatibility with a wide range of backing pads and sanding machines. This compatibility allows for a seamless transition between different grits and types of sanding discs, depending on the task at hand. Adhesive sanding discs are also appreciated for their durability and long life, as the adhesive backing can withstand repeated use without losing its stickiness.

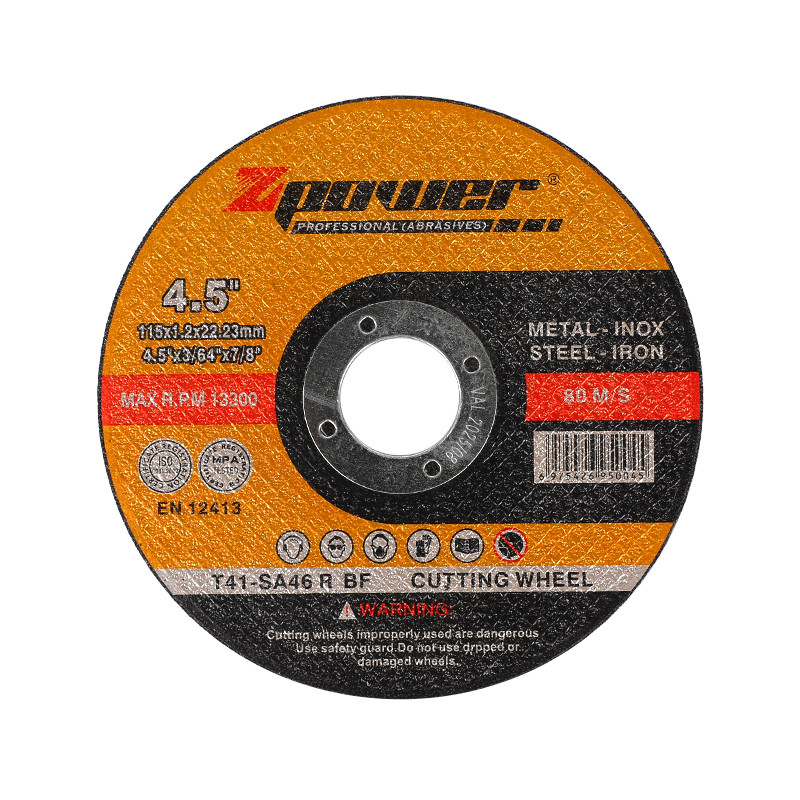

Automotive sanding discs are specifically engineered for the unique demands of automotive surface preparation. These discs are designed to handle the rigors of sanding car bodies, removing paint, and smoothing out dents and scratches. The abrasive material used in automotive sanding discs is often more aggressive than that of soft sanding discs, allowing for faster material removal and more efficient work.

One of the key features of automotive sanding discs is their ability to withstand the high speeds and pressures associated with power sanding tools. The backing material is typically more robust, ensuring that the disc does not tear or break under the strain. Additionally, automotive sanding discs are often treated with a special coating that helps to prevent clogging, which is a common issue when sanding paint and other sticky materials.

Soft sanding discs, adhesive sanding discs, and automotive sanding discs each have their own set of applications and benefits. Soft sanding discs are ideal for delicate materials and final finishing touches, providing a smooth surface without the risk of damage. Adhesive sanding discs offer the convenience of quick changes and are suitable for a variety of materials and tasks, from woodworking to metalworking. Automotive sanding discs are tailored for the demands of car body repair and refinishing, providing the durability and performance needed for these specialized tasks.

In conclusion, the choice of sanding discs depends on the specific requirements of the project at hand. Soft sanding discs provide a gentle touch for delicate surfaces, adhesive sanding discs offer versatility and convenience, and automotive sanding discs are designed to handle the rigors of car body work.

Eng

Eng  عربى

عربى