The Utility of Abrasive Disc Cutters and Cutting Face Grinding Wheels

2024.11.05

2024.11.05

Industry News

Industry News

Two such tools that have proven their worth in various applications are abrasive disc cutters and cutting face grinding wheels. These tools are not only essential in metalworking and construction but also in automotive, aerospace, and other industries where precision and quality are non-negotiable.

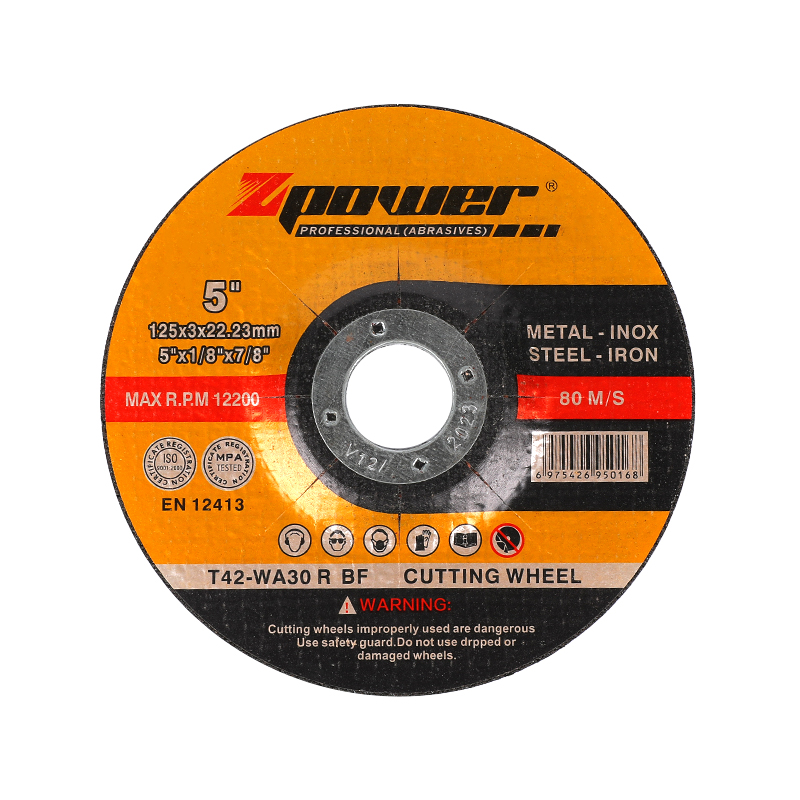

Abrasive disc cutters are designed for cutting through a variety of materials, including metal, stone, and concrete. These cutters are characterized by their circular shape and abrasive surface, which allows for rapid material removal and clean cuts. The versatility of abrasive disc cutters is evident in their ability to handle a wide range of tasks, from cutting through thick steel plates to trimming tiles and ceramics.

One of the key benefits of using abrasive disc cutters is their speed and efficiency. The abrasive material on the disc, often made from aluminum oxide or silicon carbide, can quickly erode even the hardest of materials. This results in less time spent on each cut, increasing productivity and reducing labor costs. Additionally, the precision of these cutters allows for accurate and clean cuts, small the need for additional finishing work.

Safety is another critical aspect of abrasive disc cutters. With the right safety measures in place, including the use of appropriate personal protective equipment and adherence to operating guidelines, these tools can be used with minimal risk. The discs are designed to resist breakage and heat buildup, further enhancing their safety profile.

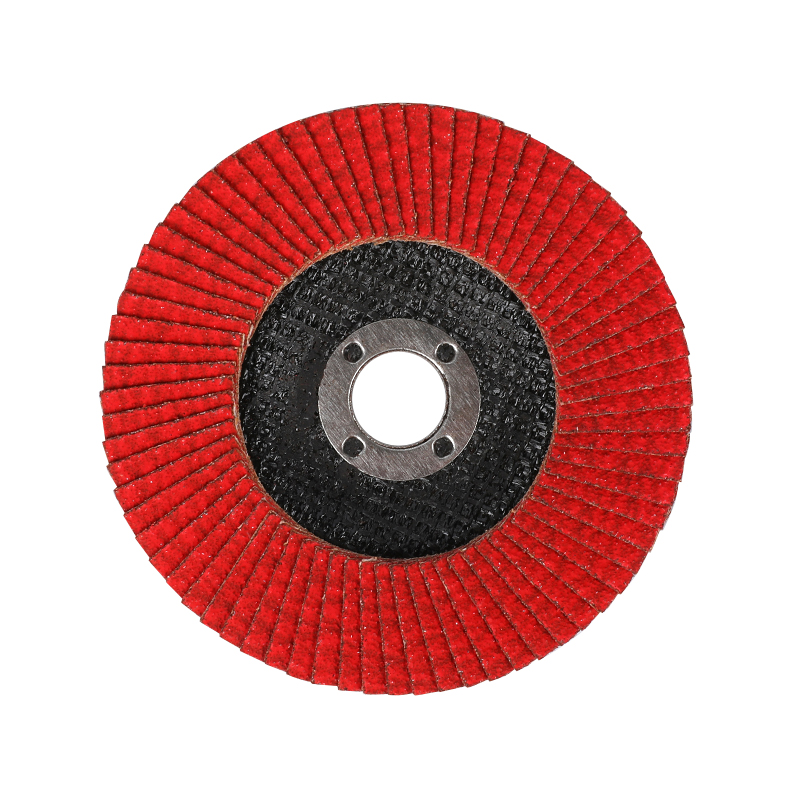

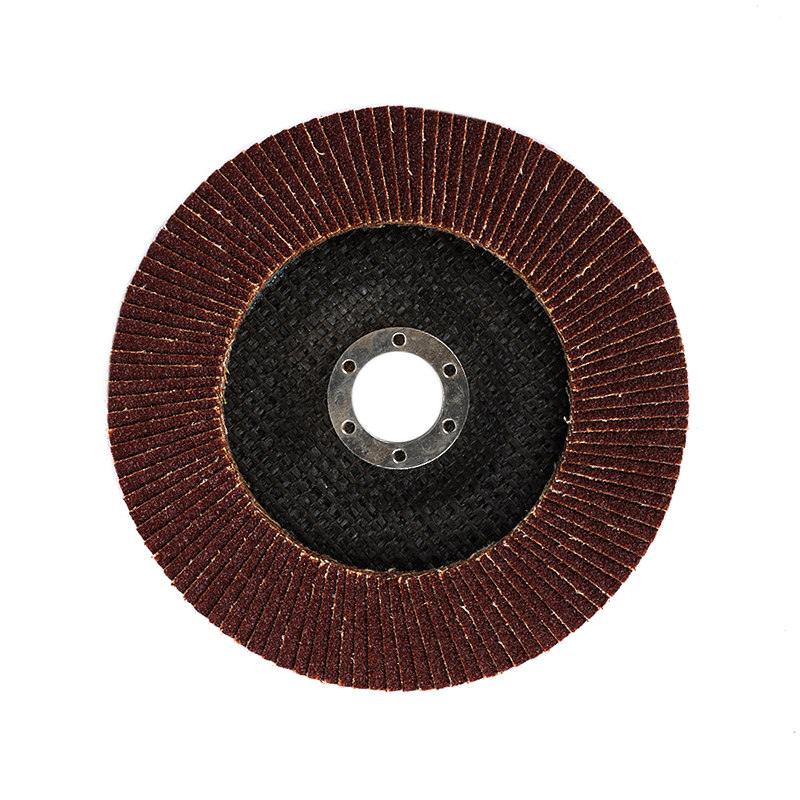

Cutting face grinding wheels are another essential tool in the arsenal of an industrial worker. These wheels are designed for grinding and shaping metal surfaces, offering a high level of precision and durability. The cutting face of these wheels is made from a hard, abrasive material that can remove material quickly and efficiently.

The precision of cutting face grinding wheels is particularly useful in applications where a high degree of accuracy is required. For instance, in the automotive industry, these wheels are used to grind and shape engine components to exact specifications. In construction, they are used to prepare surfaces for welding or to smooth out rough edges on metal structures.

Durability is another hallmark of cutting face grinding wheels. These wheels are designed to withstand the rigors of heavy-duty grinding, maintaining their shape and effectiveness over extended periods. This durability not only extends the life of the tool but also reduces the need for frequent replacements, saving both time and money.

When used in conjunction, abrasive disc cutters and cutting face grinding wheels can significantly enhance productivity in industrial settings. The cutters can be used to make initial cuts and remove large amounts of material quickly, while the grinding wheels can be employed to refine and good the surface finish. This combination of tools allows for a streamlined workflow, reducing the time spent on each task and improving overall efficiency.

In conclusion, abrasive disc cutters and cutting face grinding wheels are indispensable tools in a variety of industrial applications. Their versatility, performance, precision, and durability make them essential for achieving high-quality results in cutting and grinding tasks. By understanding the unique benefits of each tool and how they can be used together, industrial workers can big their productivity and ensure the success of their projects.

Eng

Eng  عربى

عربى