The Benefits of Curved Edge Flap Discs

2024.11.05

2024.11.05

Industry News

Industry News

Flap discs are a type of abrasive tool that has gained popularity in various industries due to their versatility and efficiency in surface preparation. They are designed to provide a consistent and even finish on a wide range of materials, from metals to wood. Among the different types of flap discs, curved edge flap discs, felt flap discs, and fine grit flap discs are particularly noteworthy for their unique characteristics and applications.

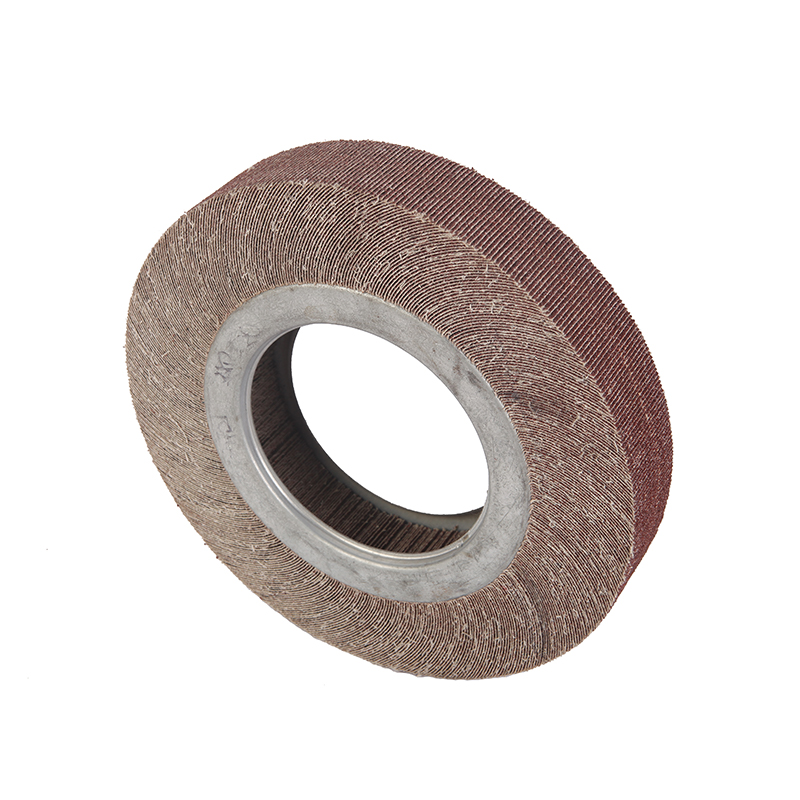

Curved edge flap discs are designed with a curved edge that allows for smooth operation and efficient deburring. These discs are ideal for applications where a curved surface or contoured edge needs to be worked on. The curved edge helps to follow the natural curve of the material, reducing the risk of gouges or uneven surfaces. This feature makes them good for use on pipes, tubes, and other cylindrical objects where a flat flap disc might not be as effective. The curved edge also provides a more comfortable grip for the user, reducing hand fatigue during extended use.

Felt flap discs are a unique type of flap disc that uses a felt material as the backing. This material is known for its ability to hold abrasive particles effectively, making these discs for polishing and finishing tasks. The felt backing is also flexible, which allows the disc to conform to the shape of the workpiece, ensuring an even distribution of abrasive material across the surface. Felt flap discs are often used in woodworking and metalworking applications where a high-quality finish is required. They are particularly effective at removing minor imgoodions and achieving a smooth, polished surface.

Fine grit flap discs are designed for precision grinding and polishing tasks. These discs feature a higher grit number, which means they have a finer abrasive particle size. This allows for a more delicate touch when working on delicate materials or when a high-gloss finish is desired. Fine grit flap discs are often used in the final stages of a project to remove any remaining imgoodions and to achieve a mirror-like finish. They are also suitable for polishing stainless steel, aluminum, and other soft metals where a coarser grit might cause damage.

One of the main benefits of using flap discs is their ability to provide a consistent and even finish. The flaps on these discs are designed to wear down evenly, which helps to maintain a consistent level of abrasiveness throughout the life of the disc. This feature is particularly important in industries where a consistent finish is critical, such as automotive and aerospace.

Another advantage of flap discs is their versatility. They can be used with a variety of power tools, including angle grinders, die grinders, and right angle grinders. This versatility allows users to tackle a wide range of tasks with a single tool, reducing the need for multiple abrasives.

When using flap discs, safety is paramount. It is essential to wear appropriate personal protective equipment, including safety glasses and gloves, to protect against flying debris and potential injury. Additionally, it is important to regularly inspect flap discs for wear and tear. Damaged or worn flap discs can become dangerous and should be replaced immediately.

In conclusion, flap discs are a valuable tool in any workshop or industrial setting. Curved edge flap discs, felt flap discs, and fine grit flap discs each offer unique benefits and are suited to specific applications.

Eng

Eng  عربى

عربى