The Benefit of Small Electroplated Diamond Angle Grinding Wheels Discs

2024.11.05

2024.11.05

Industry News

Industry News

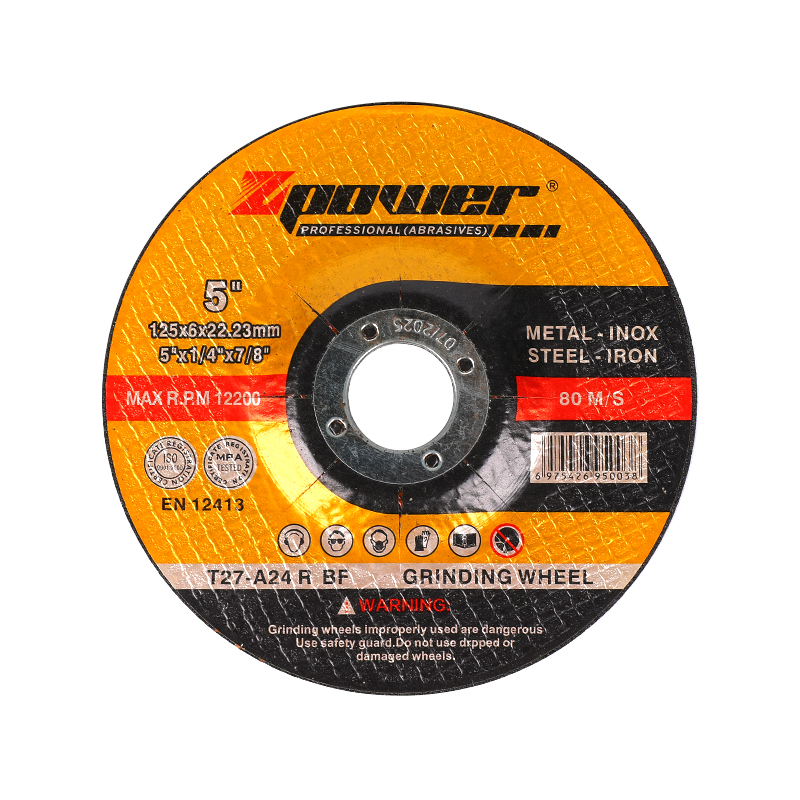

Small angle grinder discs are compact, high-speed cutting and grinding tools that are widely used in various industries. These discs are designed to fit onto angle grinders, which are handheld power tools that provide a high level of control and precision. The small size of these discs allows for work in tight spaces and intricate applications where larger tools would be impractical.

Small angle grinder discs are known for their ability to cut through a variety of materials, including metal, wood, and stone. They come in different grit sizes, which determine the coarseness or fineness of the cut. Coarser grits are used for faster material removal and rough shaping, while finer grits are ideal for smoothing and finishing tasks. These discs are also available in various bond types, which affect their durability and cutting performance.

The applications of small angle grinder discs are vast, ranging from metal fabrication and automotive repair to construction and woodworking. They are used for tasks such as cutting metal rods, grinding weld seams, removing rust, and shaping wood.

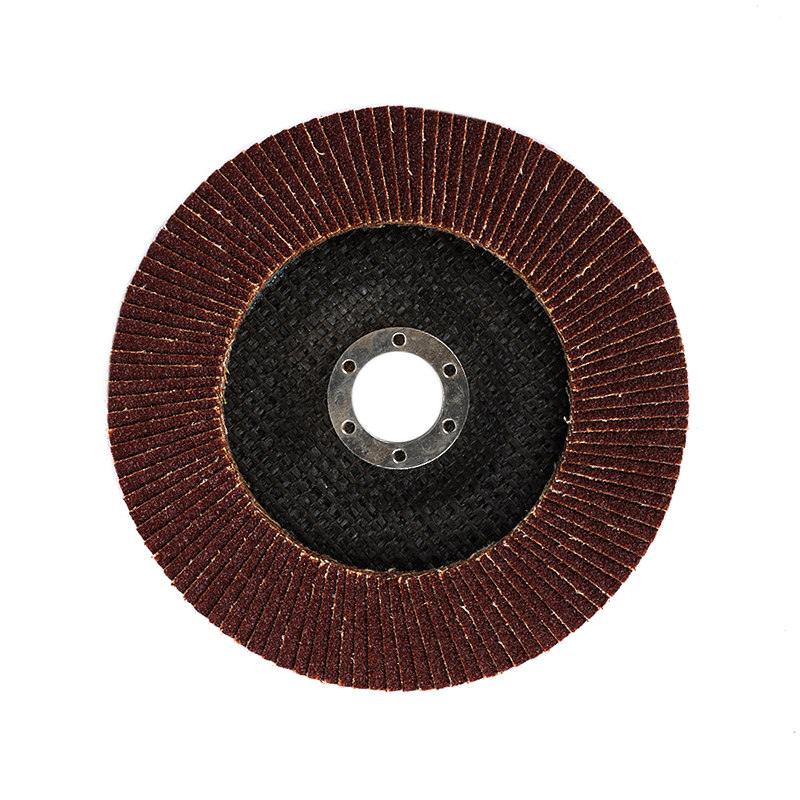

Electroplated diamond angle grinding wheels are a specialized type of abrasive tool that offers predominant performance in grinding and cutting hard materials. These wheels are coated with a layer of diamonds, which are electroplated onto the surface to create a durable and long-lasting cutting edge. The electroplating process ensures that the diamonds are evenly distributed and securely bonded to the wheel, resulting in a consistent and efficient cutting surface.

One of the key characteristics of electroplated diamond angle grinding wheels is their ability to cut through hard materials such as concrete, granite, and other stone. The diamonds provide a sharp and aggressive cutting edge that can withstand high levels of wear and tear. These wheels are also known for their long life, as the diamonds can be dressed or resharpened to maintain their cutting performance over time.

The applications of electroplated diamond angle grinding wheels are primarily in the construction and stoneworking industries. They are used for tasks such as cutting and shaping concrete, grinding down rough surfaces, and preparing stone for polishing. In the construction industry, these wheels are invaluable for cutting through reinforced concrete and other hard materials without causing damage to the embedded rebar.

Both small angle grinder discs and electroplated diamond angle grinding wheels offer a range of benefits that make them essential tools in their respective industries. Some of the key benefits include:

Precision and Control: The small size of these tools allows for precise cutting and grinding in tight spaces, providing greater control over the work being done.

Versatility: These discs can be used on a variety of materials, making them a versatile addition to any tool kit.

Durability: The high-quality materials used in the construction of these discs ensure that they can withstand the rigors of heavy-duty use.

Cost-Effectiveness: By providing a long life and consistent performance, these discs help to reduce the need for frequent replacements, saving both time and money.

Safety: The use of these tools can reduce the risk of injury associated with manual cutting and grinding, as they provide a more controlled and efficient method of working.

In conclusion, small angle grinder discs and electroplated diamond angle grinding wheels are indispensable tools in the fields of metalworking, construction, and stoneworking. Their versatility, precision, and durability make them valuable assets for professionals who demand the high level of performance from their tools.

Eng

Eng  عربى

عربى