Safety Tips for Using a Hand Grinder Wheel Effectively

2025.01.03

2025.01.03

Industry News

Industry News

Custom hand grinder wheel Maker

When it comes to using a hand grinder wheel, many users encounter common questions and challenges. Understanding these issues can significantly enhance the user experience and ensure safety during operation. This article aims to address frequently asked questions regarding the hand grinder wheel, providing practical solutions to help users navigate their concerns effectively.

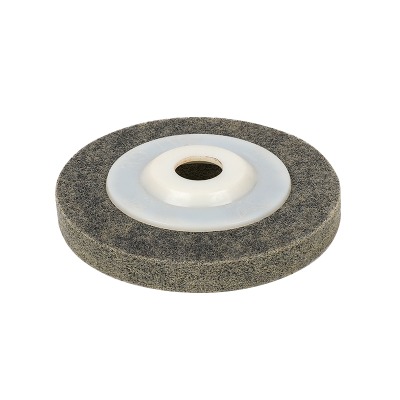

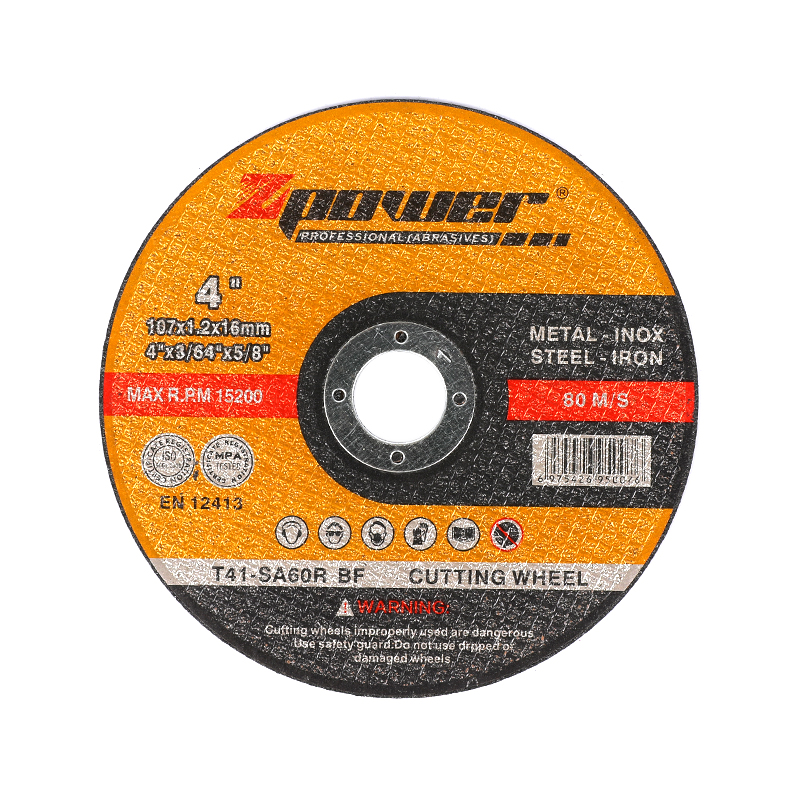

A common question is about the types of materials suitable for a hand grinder wheel. Users often wonder if they can use the same wheel for different materials. The answer is that while some wheels are versatile, it is crucial to select a hand grinder wheel specifically designed for the material you are working with. For instance, a diamond wheel is ideal for cutting hard materials like stone, while a silicon carbide wheel works well for softer materials like aluminum. Using the wrong type can cause poor results and even damage the wheel.

Another frequent concern is the lifespan of a hand grinder wheel. Users often ask how long a wheel should last and what factors influence its durability. The lifespan of a hand grinder wheel depends on several factors, including the material being ground, the pressure applied, and the speed of the grinder. Generally, a well-maintained wheel can last for many hours of use, but it is essential to inspect it regularly for signs of wear, such as cracks or uneven surfaces. If any damage is detected, it is advisable to replace the wheel immediately to ensure safety.

Safety is a paramount concern when using a hand grinder wheel. Many users inquire about the necessary protective gear. It is essential to wear safety goggles to protect your eyes from flying debris, as well as a dust mask to avoid inhaling harmful particles. Additionally, gloves can provide a better grip and protect your hands from sharp edges. Ensuring that the grinder wheel is properly secured to the grinder is also critical; a loose wheel can cause accidents.

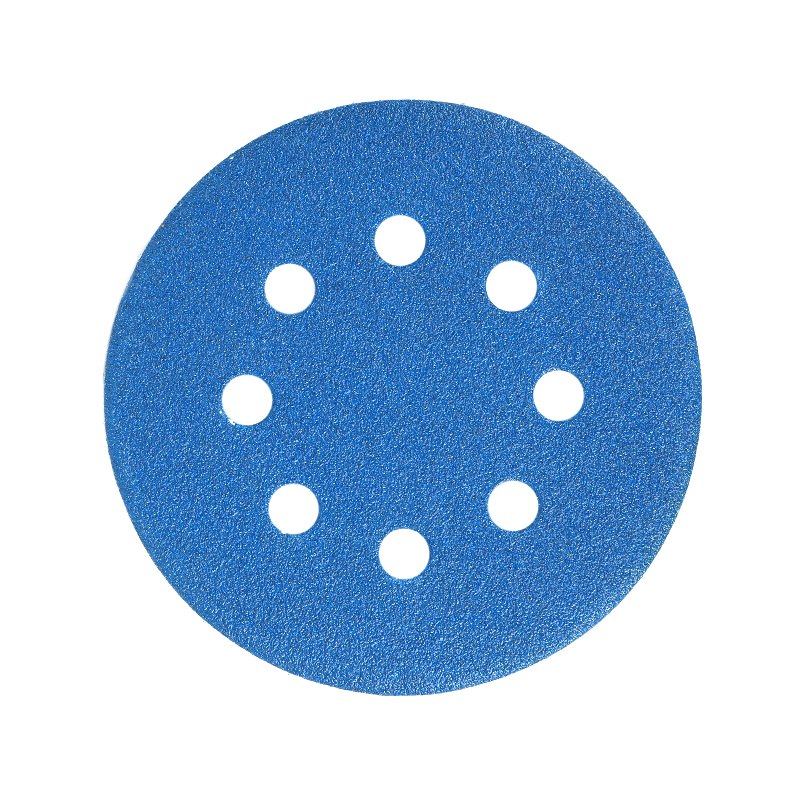

Users also frequently ask about the correct technique for using a hand grinder wheel. The key is to maintain a steady hand and apply consistent pressure. It is advisable to let the wheel do the work rather than forcing it through the material. This approach not only prolongs the life of the grinder wheel but also results in a smoother finish. Additionally, moving the grinder in a back-and-forth motion rather than a circular one can help achieve better results.

Another common question revolves around the noise produced by a hand grinder wheel. Many users find the sound level concerning, especially in residential areas. While some noise is inevitable, using a wheel designed for quieter operation can help mitigate this issue. Additionally, ensuring that the grinder is well-lubricated can reduce noise levels and improve performance.

Users often wonder about the best practices for storing a hand grinder wheel. Proper storage is crucial for maintaining the wheel's integrity. It is recommended to store wheels in a cool, dry place away from direct sunlight. Keeping them in their original packaging or a dedicated storage container can prevent damage from impacts or moisture.

Besides, users frequently ask about troubleshooting common issues with a hand grinder wheel. If the wheel is not cutting effectively, it may be due to dullness or improper alignment. In such cases, it is advisable to check the wheel for wear and replace it if necessary. If the grinder vibrates excessively, it may indicate that it is not mounted correctly or is damaged. Ensuring that the wheel is balanced and securely attached can resolve these issues.

Understanding the common questions and concerns surrounding the hand grinder wheel can significantly enhance the user experience. By selecting the right wheel for the material, maintaining safety precautions, and employing proper techniques, users can increase the effectiveness and lifespan of their hand grinder wheel. Regular maintenance and awareness of potential issues will ensure that the wheel remains a valuable tool in any workshop.

Eng

Eng  عربى

عربى