Enhancing Metalworking with Angle Grinder Discs and Polishing Grinders

2024.11.05

2024.11.05

Industry News

Industry News

Metalworking is an essential industry that relies on precision tools to achieve high-quality results. Among the many tools available, angle grinder discs and metal polishing grinders stand out for their versatility and efficiency in shaping and finishing metal surfaces.

They are designed to cut, grind, and polish various metal materials, making them a go-to tool for tasks such as weld removal, deburring, and surface preparation. These discs are known for their durability and ability to withstand high speeds, ensuring a smooth and efficient cutting process. With a wide range of grit options available, professionals can select the appropriate disc for their specific metalworking needs, from coarse grinding to fine finishing.

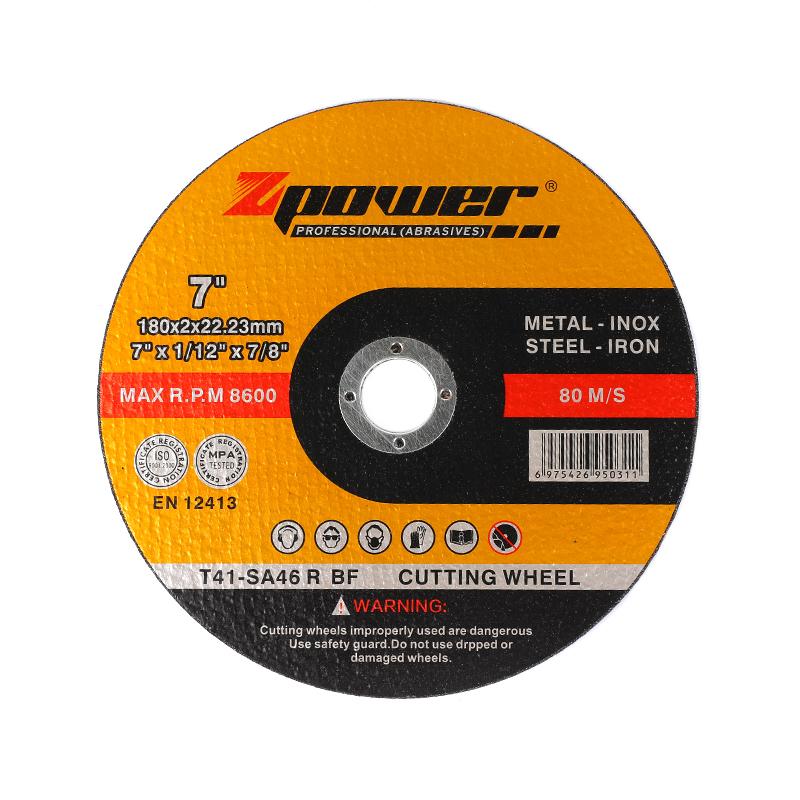

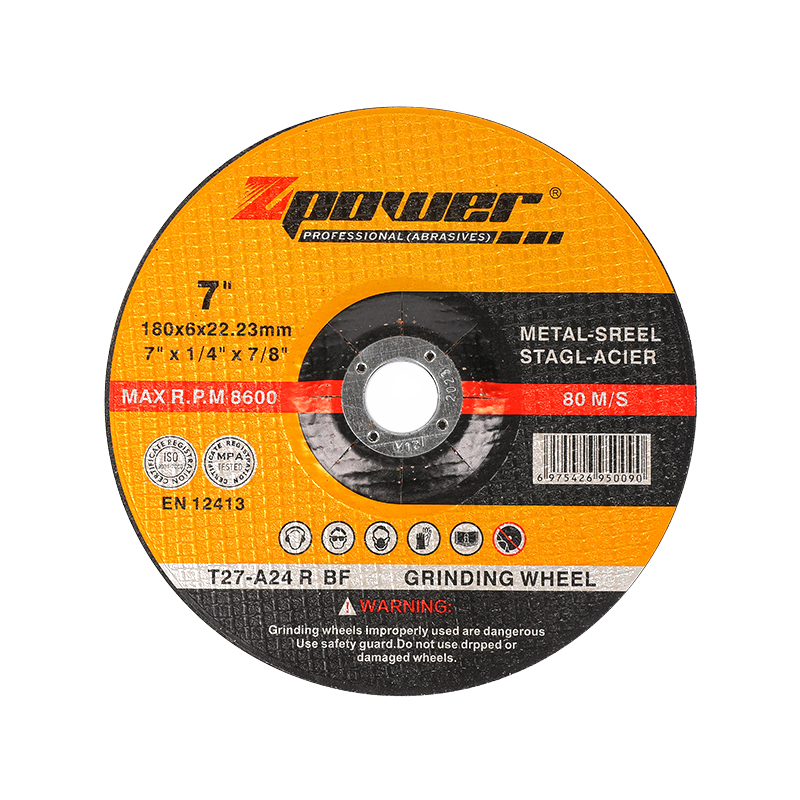

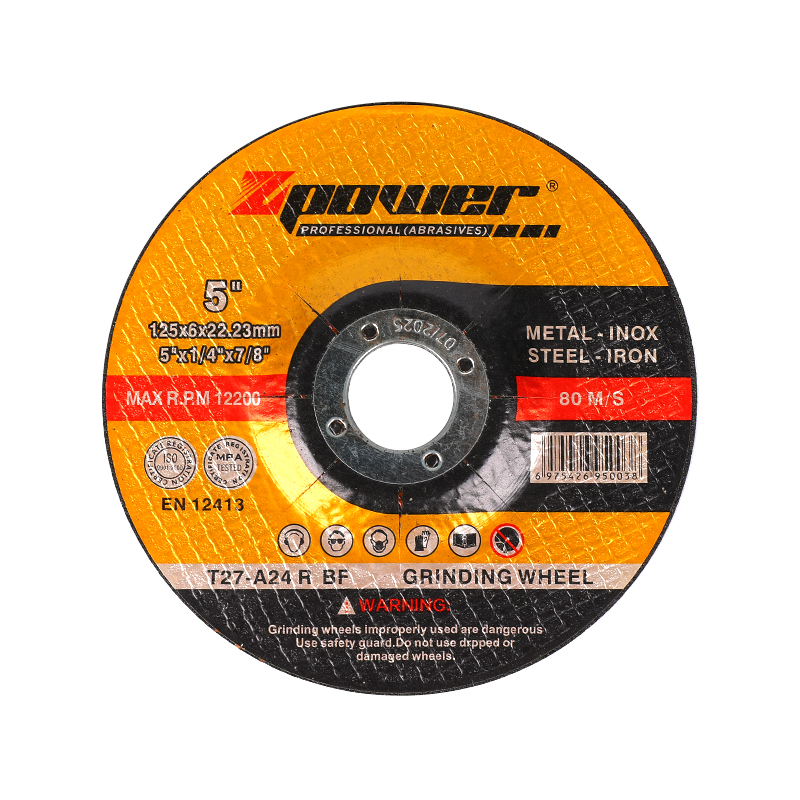

Angle grinder discs are indispensable in metalworking for their ability to cut, grind, and polish various metal materials. These discs are designed to be used with angle grinders, which are power tools that rotate at high speeds to perform abrasive tasks. The discs come in different sizes and grits, allowing for a range of applications from heavy-duty cutting to fine finishing.

Applications of Angle Grinder Discs:

1. Cutting: Angle grinder discs with a cutting wheel attachment are good for slicing through metal sheets, pipes, and bars. They offer a quick and clean cut, reducing the need for manual labor and increasing productivity.

2. Grinding: For smoothing rough edges or removing welds, grinding discs with a coarser grit are used. These discs can efficiently remove excess material and prepare surfaces for further processing or painting.

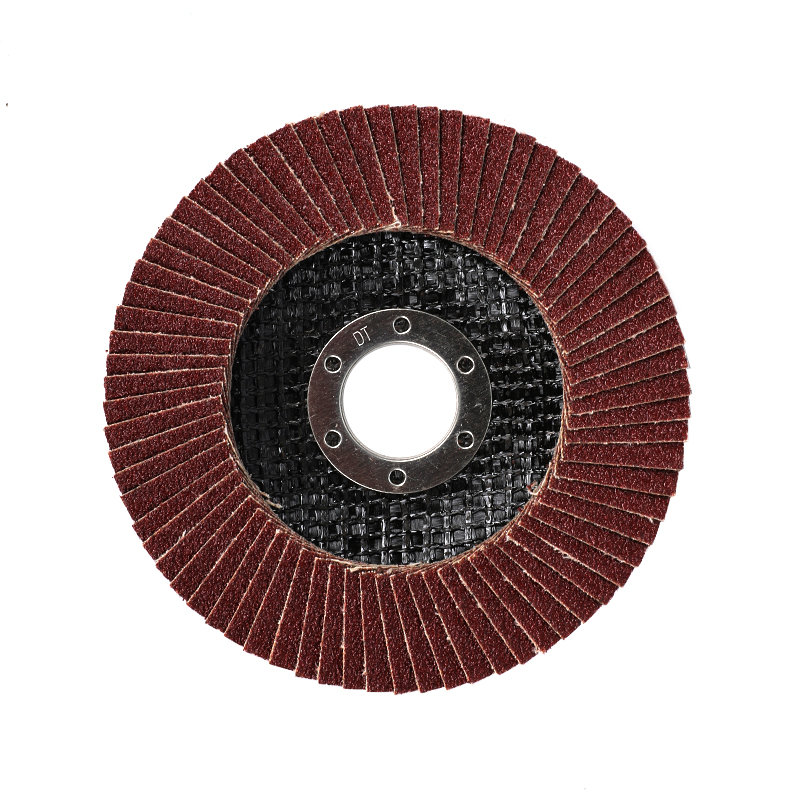

3. Polishing: Finer grit discs are used for polishing and finishing metal surfaces, giving them a smooth and shiny appearance. This is particularly important in applications where aesthetics are a priority, such as in automotive or architectural work.

Metal polishing grinders are specialized tools designed for the final stages of metal finishing. They are used to achieve a mirror-like finish on metal surfaces, which is crucial in industries where the appearance of the final product is as important as its functionality.

Benefits of Metal Polishing Grinders:

1. Enhanced Aesthetics: A polished surface not only looks professional but also protects the metal from corrosion and other environmental factors.

2. Improved Durability: The polishing process can help to seal the metal, making it more resistant to wear and tear.

3. Precision Finishing: Metal polishing grinders allow for a high level of control, ensuring that even the more intricate designs can be polished to goodion.

Selecting the appropriate angle grinder disc or metal polishing grinder is crucial for achieving the desired results. Factors to consider include the type of metal being worked on, the desired finish, and the specific task at hand. It's also important to choose discs and grinders that are compatible with the power tool being used to prevent damage and ensure safety.

Using angle grinder discs and metal polishing grinders requires adherence to safety protocols. Users should wear appropriate personal protective equipment, such as safety glasses, gloves, and ear protection. Additionally, it's essential to follow the manufacturer's guidelines for tool operation and maintenance to prevent accidents and prolong the life of the tools.

Angle grinder discs and metal polishing grinders are vital tools in the metalworking industry, offering a range of applications from cutting and grinding to polishing. By understanding the capabilities of these tools and using them correctly, metalworkers can enhance the quality and appearance of their projects.

Eng

Eng  عربى

عربى