Efficient Polishing: How to Use Sandpaper to Improve Work Efficiency

2024.12.20

2024.12.20

Industry News

Industry News

Sale polishing sanding discs Manufacturer

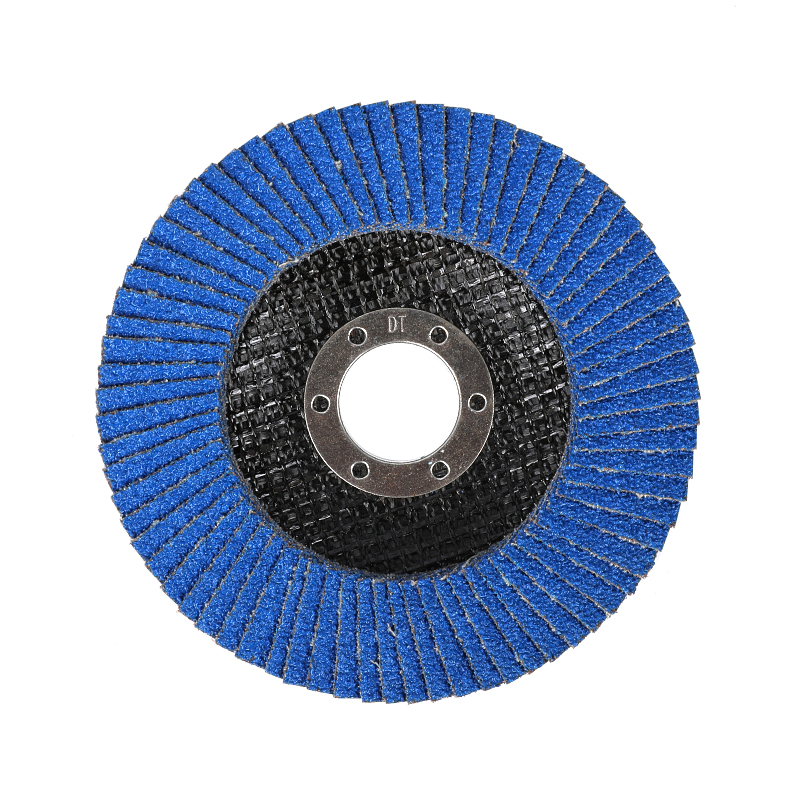

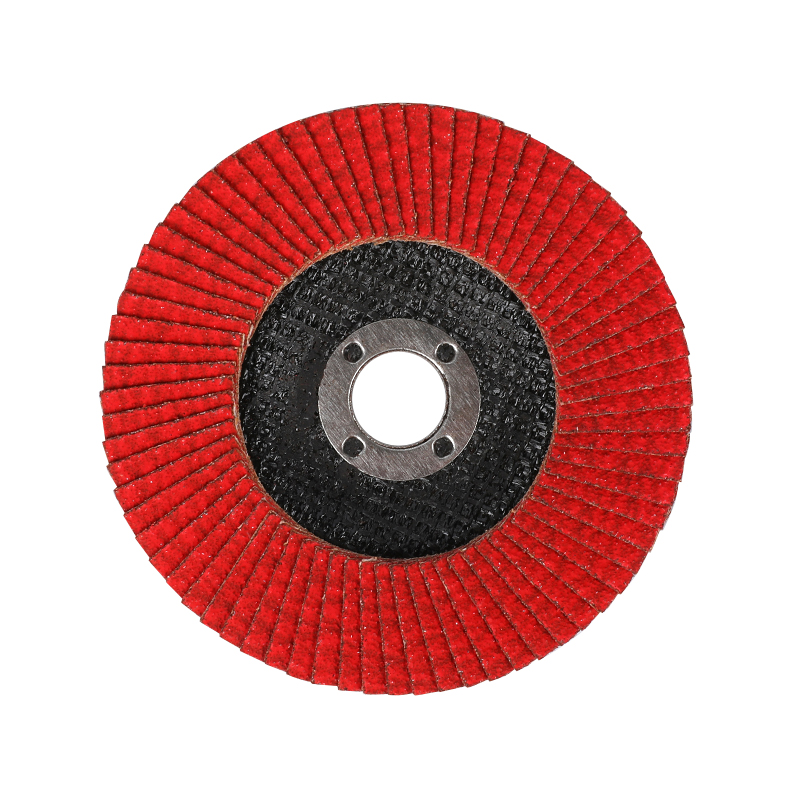

As we all know, polishing sanding discs have changed the way we approach surface finishing in various industries, from woodworking to metal fabrication. These versatile tools are designed to provide a smooth, polished finish on a wide range of materials, making them important to professionals and DIY enthusiasts alike. The effectiveness of polishing sanding discs lies not only in their design but also in their ability to adapt to different applications, ensuring good results every time.

A compelling example of the effectiveness of polishing sanding discs can be seen in the automotive industry. When restoring classic cars, achieving a flawless finish is very important. Traditional methods often involve multiple steps, including grinding, sanding, and polishing, which can be time-consuming and labor-intensive. However, with the introduction of high-quality polishing sanding discs, automotive restorers can streamline their processes. These discs allow for the quick removal of imperfections while simultaneously providing a high-gloss finish that enhances the vehicle's aesthetic appeal. The ability to switch between different grits of polishing sanding discs means that restorers can tackle various surfaces with ease, from rough metal to delicate paint finishes.

In woodworking, they have become equally essential. Craftsmen use these discs to refine their projects, ensuring that every piece of furniture or cabinetry is not only functional but also visually stunning. For instance, when finishing a hardwood table, a woodworker might start with coarse grit to remove any major flaws and then progress to finer polishing sanding discs to achieve a silky-smooth surface. This method not only saves time but also reduces the risk of damaging the wood, as the discs are designed to be gentle yet effective. The result is a beautifully polished surface that showcases the natural grain of the wood, elevating the overall quality of the finished product.

Moreover, the versatility of polishing sanding discs extends beyond just wood and metal. In the realm of electronics, these discs are used to polish and finish components, ensuring that they meet the high standards required for performance and aesthetics. For example, when preparing a smartphone casing, manufacturers utilize polishing sanding discs to eliminate any surface imperfections that could affect the device's appearance or functionality. The precision offered by these discs allows for a level of detail that is crucial in today’s competitive market.

In my opinion, the advantages of polishing sanding discs are not limited to their effectiveness; they also contribute to improved safety and efficiency in the workplace. With the ability to quickly change discs, workers can reduce downtime and maintain productivity. Additionally, the design of these discs often includes features that reduce dust and debris, creating a cleaner working environment. This is particularly important in industries where air quality is a concern, as it helps protect workers from harmful particles.

Polishing sanding discs deliver a high-quality finish on a wide range of materials, making them invaluable for professionals across various industries. In automotive restoration, they help achieve a smooth surface on car bodies, ensuring a flawless paint job. In woodworking, these discs are crucial for refining surfaces and preparing them for finishing, enhancing the overall appearance of furniture and cabinetry. In electronics manufacturing, they assist in creating precise and clean edges on components. We can anticipate even more innovations in the design and functionality of polishing sanding discs, which will further improve their effectiveness and versatility in diverse applications.

Eng

Eng  عربى

عربى