Choosing the Right Cutting Wheel for Your Angle Grinder

2024.11.05

2024.11.05

Industry News

Industry News

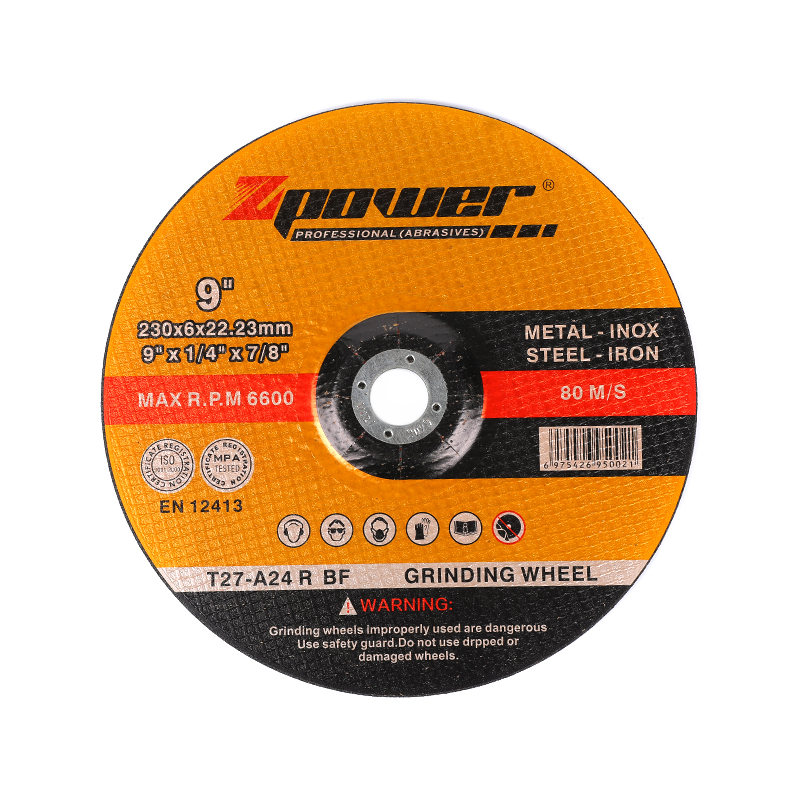

Angle grinders are versatile tools widely used in metalworking, construction, and fabrication industries. One of the key components that determine their efficiency and effectiveness is the cutting wheel. Among the various types of cutting wheels available, carbide angle grinder discs and side grinder cutting wheels stand out for their durability and performance.

Carbide angle grinder discs are cutting tools designed for use with angle grinders. They are made from tungsten carbide, a material known for its hardness and resistance to wear. This composition allows carbide discs to handle tough materials, making them suitable for cutting, grinding, and finishing applications.

These discs come in various sizes and thicknesses, catering to different tasks. Thinner discs are often preferred for cutting applications, while thicker ones are better suited for grinding and surface preparation. The choice of disc depends largely on the specific requirements of the job at hand.

Features of Carbide Angle Grinder Discs:

Durability: Carbide is significantly more durable than traditional steel, enabling the discs to maintain their cutting edges longer. This longevity translates to fewer replacements and lower overall costs over time.

Versatility: These discs can be used on a wide range of materials, including metal, masonry, and even some plastics. This adaptability makes them a valuable tool in both professional and DIY settings.

Efficiency: Carbide angle grinder discs are designed to cut quickly and cleanly. Their design smalls friction, allowing for faster work while reducing heat buildup that can damage the workpiece.

Safety Features: Many carbide discs are designed with safety in mind. They often include reinforced structures to withstand high-speed operations, which reduces the risk of breakage during use.

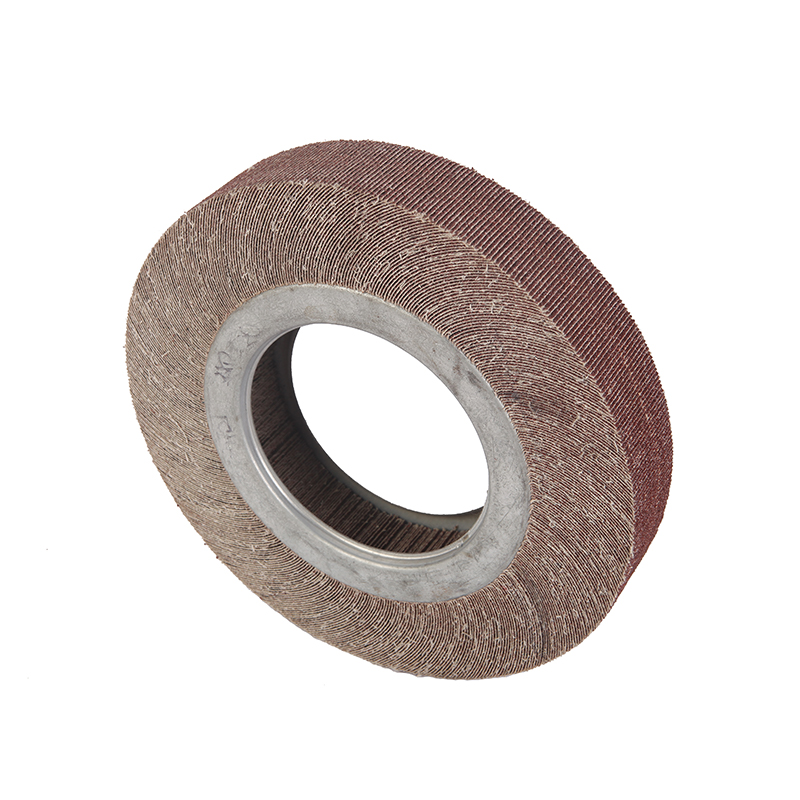

Side grinder cutting wheels often used interchangeably with carbide discs, are specifically designed for side grinding applications. These wheels are used on tools like bench grinders and angle grinders for tasks that require precision and control.

Similar to carbide discs, side grinder cutting wheels come in various materials and configurations, including bonded abrasive wheels and metal-cutting wheels. The choice of the wheel depends on the material being worked on and the desired outcome.

Both carbide angle grinder discs and side grinder cutting wheels find application in numerous industries:

Metalworking: These tools are essential in metal fabrication for cutting metal sheets, pipes, and bars. They are often used in welding preparation and post-weld cleaning.

Construction: In the construction sector, these tools assist in cutting rebar, masonry, and other hard materials. They are crucial for tasks such as demolition and renovation.

Automotive Repair: Mechanics often use carbide discs for cutting and grinding metal components, ensuring a clean finish and proper fit during repairs.

Woodworking: While primarily designed for metal and masonry, certain carbide discs can also be used for cutting hard woods, making them versatile tools for various projects.

The use of carbide angle grinder discs and side grinder cutting wheels offers several benefits:

Cost-Effectiveness: Although carbide tools may have a higher upfront cost, their durability means they last longer than traditional tools, pilot to savings in replacement costs.

Reduced Downtime: The longevity and efficiency of carbide discs mean less frequent changes are needed, small downtime and enhancing productivity.

High-Quality Finish: The precision cutting capabilities of these tools contribute to a better quality finish on the workpiece, reducing the need for additional finishing work.

Enhanced Safety: With their sturdy design and reduced likelihood of breakage, carbide discs, and wheels enhance safety during operation, providing peace of mind for users.

Carbide angle grinder discs and side grinder cutting wheels are essential tools for professionals and DIY enthusiasts alike. Their durability, versatility, and efficiency make them ideal for a wide range of applications across various industries.

Recommended Products

Quick Links

About us

Contact Info.

Copyright © 2024. YONGKANG ZHENGBO ABRASIVES CO., LTD. All rights reserved.

Aluminum Grinder Blade Factory

Eng

Eng  عربى

عربى